5 Best Fabrics for Heat Press: Top Picks for Durable and Vibrant Transfers

You’ll want fabrics like Craftido 100% cotton that offer medium weight and breathability, guaranteeing durable, vibrant heat press results without shrinkage.

Polyester blends provide excellent colorfastness, while smooth, tightly woven materials help vinyl adhere better.

Avoid rough or heavily textured fabrics that complicate transfers.

Plus, using quality tools like PTFE release sheets and a precise heat press machine improves durability.

Understanding fabric weight, texture, and heat resistance guarantees your designs last—explore these key factors more deeply to perfect your projects.

| Image | Name | Editor's Rating | Price |

|---|---|---|---|

|

Craftido-19 Options-100% Cotton Fabric b...

|

|

|

|

VINYL FROG Heat Transfer Vinyl Roll HTV ...

|

|

|

|

Liz Jordan-Hill Upholstery Fabric by The...

|

|

|

|

YRYM HT 3 Pack PTFE Teflon Sheet for Hea...

|

|

|

|

Calogy Mini Heat Press, Heat Transfer Ma...

|

|

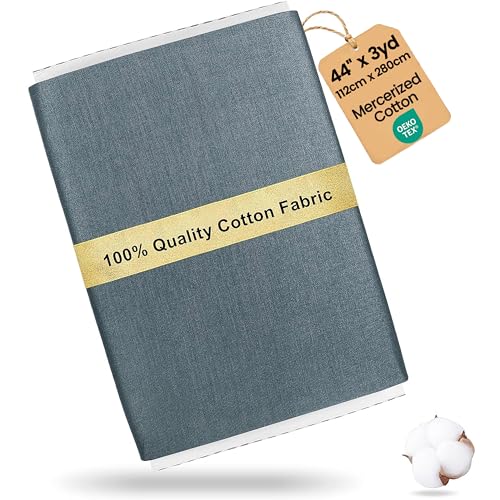

Craftido 100% Cotton Fabric by the Yard, 44″ Wide, 3 Yards, Grey

| Preview | Product | Price | |

|---|---|---|---|

|

Craftido-19 Options-100% Cotton Fabric by The Yard in Solid Color... | Buy Now |

Craftido 100% Cotton Fabric offers a reliable and soft material perfect for various crafting needs. This grey fabric is 44 inches wide and comes in a 3-yard length, providing enough fabric for multiple projects. Its medium weight ensures durability and breathability, making it ideal for heat press applications.

Made from premium cotton, this fabric resists shrinkage and feels comfortable to work with. The solid grey color provides a neutral base that enhances the visibility of heat press transfers. It is suitable for quilting, sewing, and creating items like bags, pillows, or baby clothes.

Best for: Crafters and DIY enthusiasts seeking a durable, breathable, and soft cotton fabric for quilting and heat press projects.

Pros:

- 100% premium cotton with minimal shrinkage and a soft feel

- Medium weight suitable for a variety of sewing and crafting projects

- Solid grey color improves transfer vibrancy and clarity

Cons:

- Limited to a solid grey color, which might not suit all design preferences

- Medium weight may not be ideal for very lightweight or heavy-duty uses

- Sold in 3-yard increments, which could be more than needed for smaller projects

VINYL FROG Heat Transfer Vinyl Roll 12″ x 5ft Grey for T-Shirts and DIY Crafts

| Preview | Product | Price | |

|---|---|---|---|

|

VINYL FROG Heat Transfer Vinyl Roll HTV Vinyl - 12" x5ft Grey Iron on... | Buy Now |

The VINYL FROG Heat Transfer Vinyl Roll offers a soft, stretchable polyurethane material designed for lasting use on various fabrics. Its sleek grey color adds a modern touch to your projects. This vinyl applies smoothly with a home iron at 302-320°F for 10-12 seconds and peels cold to ensure strong adhesion.

It works well on cotton, polyester, rayon, and blends, resisting cracking, fading, and flaking even after multiple washes. The vinyl is eco-friendly and certified safe for all garments, including children’s clothing. You can layer it to create multi-color designs on t-shirts, hoodies, bags, and more.

Best for: Craft enthusiasts and DIYers seeking a durable, versatile vinyl for customizing fabric items.

Pros:

- Soft, stretchable polyurethane that adheres well to multiple fabric types.

- Resists cracking, fading, and flaking through repeated washing.

- Eco-friendly and safe for all garments, including children’s clothing.

- Suitable for layering to create complex designs.

Cons:

- May require multiple cuts for larger designs due to 12″ width.

- Precise temperature and pressure needed for optimal results.

- Cold peel process might extend project time compared to warm peel options.

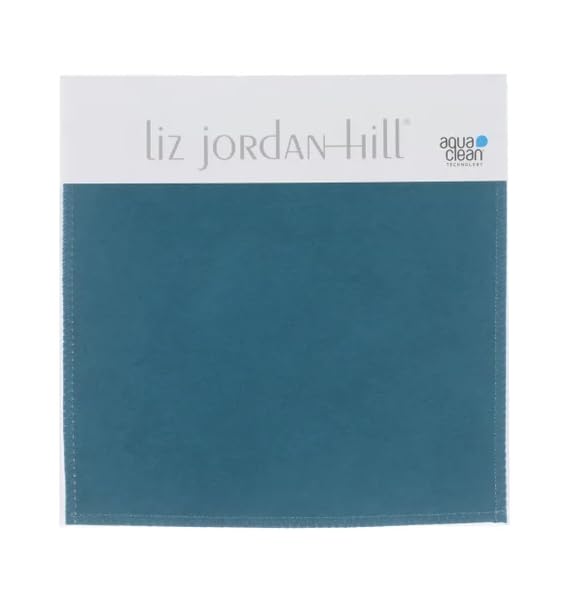

Liz Jordan-Hill Teal Luxury Microsuede Upholstery Fabric (Sample)

| Preview | Product | Price | |

|---|---|---|---|

|

Liz Jordan-Hill Upholstery Fabric by The Yard – Luxury Microsuede... | Buy Now |

The Liz Jordan-Hill Teal Luxury Microsuede Upholstery Fabric features built-in stain resistance and water-cleanable fibers. Its advanced Aquaclean technology creates an invisible nano-barrier that repels liquids and lifts stains using only water. This fabric offers high durability with over 75,000 double rubs abrasion resistance, suitable for heavy-use furniture.

It is also resistant to cat scratches, making it a practical choice for pet owners. The medium-weight material combines luxury with functionality, ideal for both residential and commercial upholstery. To ensure the color and texture meet your needs, ordering a sample is recommended before purchasing.

Best for: homeowners or businesses looking for a durable, easy-to-clean, and pet-friendly upholstery fabric.

Pros:

- Built-in Aquaclean technology for stain removal with water

- High abrasion resistance with over 75,000 double rubs

- Resists cat scratches, suitable for pet-friendly environments

- Medium-weight fabric balances durability and comfort

Cons:

- Color and texture may vary; sample recommended before purchase

- Medium weight might not suit very lightweight or delicate projects

- Specialty fabric may be less common than standard upholstery options

3 Pack PTFE Teflon Heat Press Transfer Sheets (16 x 20″)

| Preview | Product | Price | |

|---|---|---|---|

|

3 Pack PTFE Teflon Sheet for Heat Press Transfer Sheet Non Stick 16 x... | Buy Now |

The 3 Pack PTFE Teflon Heat Press Transfer Sheets offer excellent protection for your work surface. They resist heat up to 600°F, making them suitable for various heat pressing and ironing tasks. These sheets are crafted from thick, tear-resistant material that is both reusable and durable.

Their non-stick, waterproof design allows for easy cleanup. Glue, wax, or clay residues wipe off effortlessly. You can trim the sheets to fit different project sizes, providing flexibility in use. These sheets also work well for baking, ensuring your materials stay safe without damage.

Best for: Crafters and heat press users seeking reliable, reusable sheets to protect surfaces during heat transfer and other crafting projects.

Pros:

- High heat resistance up to 600°F safeguards surfaces.

- Non-stick and waterproof for easy cleaning.

- Durable and tear-resistant for repeated use.

Cons:

- May require trimming to fit specific projects.

- Could be less suited for heavy-duty industrial uses.

- Limited to applications under 600°F.

Calogy Mini Heat Press Machine for Crafts and Apparel (White Pink)

| Preview | Product | Price | |

|---|---|---|---|

|

Calogy Mini Heat Press, Heat Transfer Machine, Constant Temp Control,... | Buy Now |

The Calogy Mini Heat Press Machine offers a compact design ideal for small heat transfer projects. Its heat plate measures 2.87 by 4.43 inches, making it suitable for crafting on T-shirts, hats, and pillows. The device features a simple one-button temperature control with three preset settings: 284 ℉, 320 ℉, and 356 ℉.

This mini heat press heats up quickly and includes safety features like an auto shut-off and insulated base for protection during use. The ergonomic handle and removable power cord add to its ease of handling and storage. It is designed specifically for detailed, personalized designs on smaller items.

Best for: Hobbyists and craft enthusiasts seeking a user-friendly heat press for small apparel and accessory projects.

Pros:

- Compact heat plate tailored for small or unique items

- Easy one-button temperature control with fast heating

- Safety features such as auto shut-off and insulated base

- Ergonomic handle and removable power cord for convenience

Cons:

- Heat plate size might limit larger transfer applications

- Temperature settings are preset without fine adjustment

- Primarily suited for small-scale, non-commercial use

Factors to Consider When Choosing Fabric for Heat Press

When choosing fabric for heat press, you need to take into account the material type and how well it handles heat. The fabric’s weight and surface texture also affect the final result, so pay attention to those details.

Don’t forget to check if the fabric maintains its color under high temperatures to guarantee lasting quality.

Fabric Material Type

Choosing the right fabric material plays an essential role in achieving successful heat press results. You’ll want to take into account the type of fabric since cotton, polyester, and blends each handle heat and adhesion differently.

Cotton and cotton blends are typically ideal for heat transfer vinyl because they withstand high temperatures without melting or warping. Polyester can work too, but you’ll need to use lower temperatures to avoid damage. Don’t forget to check the fabric’s weight and texture—heavier fabrics often require more pressure and heat for the design to stick well.

Always verify the manufacturer’s specifications for heat press compatibility. This guarantees your transfer lasts longer and looks vibrant after repeated washes. Choosing wisely prevents wasted materials and disappointing results.

Heat Resistance Level

Heat resistance plays a vital role in determining which fabrics work best for heat press applications. If your fabric can’t handle the heat, it may warp or degrade, ruining your design. Aim for fabrics that withstand temperatures between 280°F and 400°F, depending on your heat transfer vinyl.

Polyester and cotton blends usually offer better heat resistance than pure cotton, making them more versatile for different heat press methods. Always check the fabric’s heat resistance guidelines and the manufacturer’s recommendations to avoid damage and guarantee your transfers last through multiple presses.

Fabric Weight Impact

Besides heat resistance, fabric weight plays a major role in how your design turns out under the heat press. Fabric weight, measured in ounces per square yard or grams per square meter, affects how heat and pressure interact with your material. Medium-weight fabrics, around 5.2 oz (145 g/m²), offer a great balance of durability and flexibility, making them ideal for most heat transfer projects.

If you choose lighter fabrics, you’ll need to lower heat and pressure settings to prevent scorching or damage. On the other hand, heavier fabrics can handle higher temperatures and stronger pressure, often leading to better adhesion for your design. Knowing your fabric’s weight helps you set the right temperature and application time, ensuring your transfers last without harming the fabric.

Colorfastness Under Heat

While applying heat to transfer your design, you need to contemplate how well the fabric holds its color under high temperatures. This quality, known as colorfastness, is essential because some fabrics fade or bleed when heated. Synthetic materials like polyester generally offer better colorfastness than natural fibers such as cotton.

Even though heat transfer vinyl (HTV) resists fading, the fabric beneath must also maintain its color to keep your design vibrant. To avoid surprises, always check the fabric’s dye quality and finishing or run a wash test before heat pressing. Choosing fabrics with proven high colorfastness guarantees your transfers stay sharp and colorful, making your finished product look professional and last longer.

Surface Texture Influence

Surface texture plays an essential role in how well your heat transfer vinyl sticks and lasts on fabric. Smooth fabrics with tight weaves, like cotton or polyester blends, generally offer better adhesion and durability. Rough or highly textured surfaces can make it harder for the vinyl to bond securely, often requiring more pressure and longer heat press times.

Be cautious with fabrics featuring embroidery or prints, as these embellishments can interfere with adhesion and damage your design. To avoid surprises, always test a small fabric sample first. This helps you gauge how well the transfer material will adhere and whether you need to tweak your pressure, temperature, or time settings for the best results.

Prioritizing surface texture guarantees your design stays vibrant and intact.

Shrinkage and Stretch

After ensuring your fabric’s texture supports strong adhesion, you should also think about how the material handles shrinkage and stretch. Some fabrics shrink considerably after washing, which can distort your final design. Choosing medium-weight cotton or similar fabrics with minimal shrinkage helps maintain shape and design integrity.

Stretchability matters too—fabrics blended with polyurethane stretch without warping the design during heat pressing. You’ll want materials with good recovery properties, so they bounce back to their original shape after stretching, preserving your transfer’s durability. To be sure your fabric can handle the heat press process, consider performing a burn test to check composition.

This way, you avoid materials that might melt or warp under heat, ensuring your project lasts longer and looks vibrant after every wash.

Breathability and Comfort

Since you’ll be wearing heat-pressed garments for extended periods, choosing breathable fabrics is key to staying comfortable. Breathability lets air circulate, preventing heat buildup and excessive sweating, especially in warm conditions. Cotton stands out because its natural fiber structure promotes airflow, making it a top pick for heat transfer projects.

You’ll want to take into account fabric weight too; medium-weight materials around 5.2 oz strike a great balance between durability and comfort. Don’t forget softness—smoother fabrics feel better against your skin, particularly where heat transfers sit. By selecting breathable, soft, and appropriately weighted fabrics, you maintain your heat-pressed garments stay comfortable all day without trapping heat or causing irritation.

This thoughtful choice enhances wearability and keeps your designs looking fresh.

Compatibility With Transfers

Choosing fabric that works well with heat transfer materials is essential for durable, vibrant designs. When picking fabric, check if it’s compatible with heat transfer vinyl (HTV) or other transfer types, focusing on cotton, polyester, or blends. Fabrics with high cotton content, like 100% cotton, generally offer better adhesion and long-lasting results after washing.

Be cautious with high polyester fabrics, as some transfers can’t handle the heat needed, causing peeling or fading. Medium-weight fabrics provide the right stability for your designs under heat pressing. Always test a small fabric swatch with your chosen transfer method before starting a larger project.

This guarantees compatibility and helps avoid wasting materials while assuring the best outcome for your heat press creations.

Frequently Asked Questions

Can Heat Press Damage Synthetic Fabrics Over Time?

Yes, heat pressing can damage synthetic fabrics over time if you use too much heat or press for too long.

You should always follow temperature guidelines to keep your fabrics looking great and avoid melting or warping.

What Is the Best Temperature Setting for Different Fabric Blends?

You should set 320°F for cotton blends, 300°F for polyester, and 280°F for delicate fabrics like rayon.

Always check your material’s care tag and test on a scrap to avoid scorching or damage during heat pressing.

How Do Fabric Texture and Weave Affect Transfer Quality?

Fabric texture and weave affect transfer quality like a rough wall affects paint—you’ll get uneven adhesion on coarse weaves or textured fabrics.

You’ll want smooth, tight weaves for crisp, vibrant transfers that last longer and look sharp.

Are There Eco-Friendly Fabrics Suitable for Heat Pressing?

Yes, you can use eco-friendly fabrics like organic cotton, bamboo, and hemp for heat pressing. They hold transfers well, reduce environmental impact, and keep your designs vibrant while supporting sustainable fashion choices.

Can Heat Pressing Be Used on Pre-Washed or Treated Fabrics?

Yes, you can heat press on pre-washed or treated fabrics. Just make sure they’re fully dry and smooth.

Pre-washing helps remove chemicals, improving transfer quality, so your designs last longer and look vibrant after pressing.

Conclusion

When choosing fabric for your heat press projects, think of it as picking the perfect canvas for your masterpiece. Cotton offers durability and vibrancy, while vinyl and microsuede bring unique textures and finishes.

Don’t forget quality accessories like Teflon sheets and reliable machines to keep your transfers crisp and bright. With the right materials, your creations won’t just stick—they’ll shine, lasting through every wash and wear like a work of art.