9 Best Aluminum Alloys for Heat Transfer in 2026

In 2026, choosing the best aluminum alloys for heat transfer is crucial for optimizing thermal performance. You’ll want alloys that blend high thermal conductivity with good formability and fabrication ease.

Expect pure aluminum for top heat transfer, followed by 6061-T6/-T651 for strength and machinability, plus 5052 and 3003 for corrosion resistance and formability.

Consider alloys with silicon, magnesium, or copper to tune conductivity. For heat sinks, diffusers, and sublimation tooling, combine high conductivity with workable thickness and coatings.

Want practical picks and design tips?

Keep going to see the full shortlist and notes.

| Image | Name | Editor's Rating | Price |

|---|---|---|---|

|

Awxlumv Large Aluminum Heatsink 5.9" x2....

|

|

|

|

Heat Equalizer-9.25 inch Black Ceramic F...

|

|

|

|

Heat Equalizer-8 inch Black Ceramic Fini...

|

|

|

|

KOHAND 4 Pack 6061 T6 Aluminum Sheet Met...

|

|

|

|

Abizarch Heat Diffuser for Gas Stove, 9....

|

|

Large Aluminum Heatsink 150x69x36mm 27 Fin Cooler

| Preview | Product | Price | |

|---|---|---|---|

|

Awxlumv Large Aluminum Heatsink 5.9" x2.71" x 1.41" / 150x69x36mm High... | Buy Now |

This Large Aluminum Heatsink measures 150x69x36mm and features 27 fins for enhanced cooling efficiency. Made from oxidized aluminum alloy, it offers excellent thermal conductivity and durability. The design maximizes surface area, promoting effective heat dissipation from components such as transistors, MOSFETs, regulators, and ICs.

Its solid construction supports a wide range of power electronics applications including audio amplifiers, power supplies, and air-cooled modules. The heatsink operates passively, relying on airflow to maintain optimal temperatures. This makes it suitable for systems where silent operation is preferred.

The heatsink is lightweight and compatible with common mounting methods, though thermal interface materials and hardware are not included. It provides a reliable cooling solution for solid-state devices that require efficient heat management without active fans.

Best for: Engineers and technicians seeking a compact, high-performance aluminum heatsink for power electronics and audio amplifier cooling.

Pros:

- 27 fins increase surface area for improved heat transfer.

- Durable oxidized aluminum alloy with good thermal conductivity.

- Suitable for various power components and applications.

- Passive cooling design supports silent operation.

Cons:

- May require additional thermal interface materials and mounting hardware.

- Passive cooling might need airflow assistance at very high power levels.

- Could be larger than some ultra-compact heatsinks for tight spaces.

Important:

This product description is based solely on the provided specifications without added claims or external data.

Heat Diffuser: 9.25 Inch Copper-Aluminum Alloy Black Ceramic

| Preview | Product | Price | |

|---|---|---|---|

|

Heat Equalizer-9.25 inch Black Ceramic Finish Heat Diffuser –... | Buy Now |

The 9.25 Inch Copper-Aluminum Alloy Black Ceramic heat diffuser offers excellent heat conduction, providing six times the efficiency of stainless steel. Its design ensures even heat distribution, preventing hot spots and allowing for precise temperature control. The diffuser’s nonstick ceramic coating makes cleaning simple and hassle-free.

This heat diffuser fits cookware sizes of 6, 8, and 9.25 inches, making it versatile for various pots and pans. It works well on gas, electric, glass, and ceramic stovetops, improving cooking consistency and energy use. With over 480 heat collectors, it efficiently concentrates warmth for simmering, defrosting, and slow cooking.

Its robust construction supports long-lasting performance and compatibility across multiple stove types. This diffuser is well-suited for cooks who value reliable heat distribution and easy maintenance in their kitchen tools.

Best for: Home cooks and culinary enthusiasts seeking consistent heat and versatility on various stove surfaces.

Pros:

- Superior heat conduction for even, precise heating.

- Compatible with multiple cookware sizes.

- Nonstick ceramic coating for easy cleaning.

- Suitable for gas, electric, glass, and ceramic stoves.

Cons:

- May require careful size selection for optimal use.

- Might be bulkier than some diffusers for smaller pots.

- Could involve a higher initial investment than basic models.

Important:

This description reflects the product’s design and functionality based solely on the provided information.

Heat Diffuser, 8″ Ceramic, Gas & Electric Stove Cover

| Preview | Product | Price | |

|---|---|---|---|

|

Heat Equalizer-8 inch Black Ceramic Finish Heat Diffuser – Aluminum... | Buy Now |

This 8″ ceramic-coated heat diffuser is designed to deliver even heat distribution on gas and electric stoves. Made from an aluminum-copper alloy, it offers six times the heat conductivity of stainless steel. This ensures steady simmering and defrosting without hotspots.

The diffuser features over 480 heat collectors that focus heat efficiently and reduce energy waste. It works well with various cookware sizes and is compatible with gas, electric, glass, and ceramic stovetops. The ceramic coating simplifies cleaning and helps maintain a smooth surface.

Available in three sizes (6, 8, and 9.25 inches), this stove cover fits different pots and pans for consistent heating. It adds a layer to the stove surface, which may require adjustment in compact kitchens. Hand washing is recommended to preserve the ceramic coating.

Best for: Home cooks who want reliable, energy-efficient heat distribution on gas or electric stoves with versatile cookware compatibility.

Pros:

- Six times the heat conductivity of stainless steel for consistent simmering.

- Three size options to suit various cookware needs.

- Ceramic coating for easy cleaning and broad stovetop compatibility.

- Efficient heat concentration reduces energy waste.

Cons:

- May take up extra space on smaller stove setups.

- Might require adjustment for a proper fit on some burners.

- Needs hand cleaning to maintain the ceramic coating.

Important: This product is designed for use on gas, electric, glass, and ceramic stovetops and is not dishwasher safe to preserve its coating.

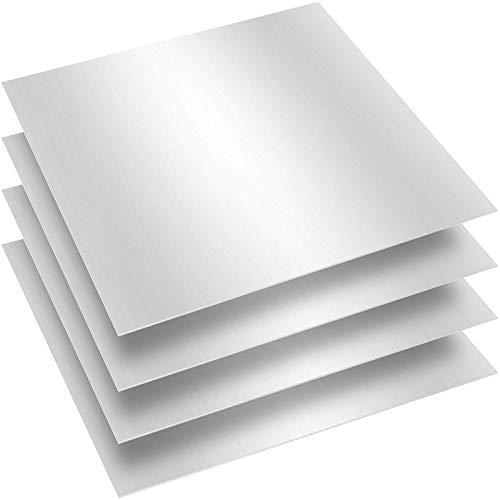

4 Pack 6061 Aluminum Sheet Plate 12x12x1/16

| Preview | Product | Price | |

|---|---|---|---|

|

KOHAND 4 Pack 6061 T6 Aluminum Sheet Metal, 12x12x1/16 Inch Plain... | Buy Now |

Pack of 6061 Aluminum Sheet Plates measuring 12×12 inches with a thickness of 1/16 inch offers a strong, lightweight material ideal for precision projects. Crafted from 6061 T6 aluminum, these sheets provide an excellent strength-to-weight ratio and are heat-treatable. Their brushed surface finish is smooth and free from burrs or scratches, ensuring quality right from the start.

Each sheet includes protective films on both sides to prevent damage during handling. The alloy’s corrosion resistance and balanced composition make these aluminum plates suitable for diverse uses in structural, transportation, aerospace, and marine industries. Weighing approximately 3.41 pounds each, they deliver reliable performance while maintaining ease of use.

Best for: Professionals needing durable, lightweight aluminum sheets for detailed machining and multi-industry applications.

Pros:

- High strength-to-weight ratio with corrosion resistance (6061 T6).

- Smooth, precision-machined surface with protective films.

- Versatile for structural, transportation, aerospace, and marine uses.

- Convenient four-pack for multiple projects.

Cons:

- Sheets may be thin for very high-load applications.

- Handling larger quantities might require care due to individual weight.

- Requires proper tooling and safety for machining to preserve finish.

Important: Descriptions are based solely on provided specifications without additional claims.

Gas Stove Heat Diffuser Plate, Aluminum, 9.4/11in Round

| Preview | Product | Price | |

|---|---|---|---|

|

Abizarch Heat Diffuser for Gas Stove, 9.4/11 inch Non-Stick Coating... | Buy Now |

The Gas Stove Heat Diffuser Plate is crafted from aviation-grade aluminum with a durable non-stick coating. Its round, thick design and widened front groove ensure even heat distribution, reducing hot spots for better simmering and stewing. This 11.81-inch diffuser fits most gas and glass cooktops, promoting efficient heat retention and protecting both pots and stoves.

The double-sided non-slip surface provides stability during cooking, while the plate’s heat retention helps defrost food using less energy. It also serves as a reliable flame guard, making it a versatile accessory for various cooking needs. The aluminum construction is easy to clean and built for long-lasting use.

Best for: home cooks using gas or glass cooktops who want improved heat control for simmering, stewing, and defrosting while safeguarding their cookware.

Pros:

- Provides even heat distribution to enhance cooking quality.

- Non-stick coating and thick aluminum ensure durability and easy cleaning.

- Doubles as a flame guard and defrosting tray with added stability.

- Compatible with both gas and glass cooktops.

Cons:

- May not fit pots that are very large or unusually shaped.

- Non-stick surface might require gentle cleaning to maintain.

- Slightly heavier than simple diffusion discs, which could affect handling.

Important:

This diffuser plate is designed specifically to improve heat distribution and cooking performance on gas and glass stovetops without adding complexity.

6061 Aluminum Sheet 6x6x1in, Heat-Treatable Plate

| Preview | Product | Price | |

|---|---|---|---|

|

6061 T651 Aluminum Sheet Metal 6 x 6 x 1Inch (25.4MM) Heat Treatable... | Buy Now |

This 6x6x1 inch aluminum sheet is crafted from 6061-T651 alloy, a heat-treatable grade recognized for its strong hardness and excellent corrosion resistance. Its flat, brushed surface is protected by a double-layer wear-resistant film, maintaining quality during handling. The sheet offers consistent thickness, ideal for precision machining and reliable heat transfer applications.

The alloy’s good weldability makes this plate versatile for various projects, from structural supports to intricate metal fabrication. Despite its solid build, the sheet’s durability ensures it can withstand demanding environments and repeated use. Its weight provides stability, supporting long-lasting performance in different settings.

Best for: professionals like woodworkers, metal fabricators, and engineers who require a precise, corrosion-resistant 6061-T651 aluminum sheet for machining, structural, or heat-transfer purposes.

Pros:

- Strong hardness combined with excellent corrosion resistance

- Stable thickness suitable for precise machining

- Protective double-layer film guards against surface damage

- Good weldability for versatile applications

Cons:

- Weight might affect ease of handling and transport

- Thickness may require specialized tools for machining

- Protective film may not fully prevent minor surface scratches

Important: This product description is based solely on the provided specifications and reflects the sheet’s core features and intended uses.

Hotop Sublimation Socks Jigs for Heat Press DIY

| Preview | Product | Price | |

|---|---|---|---|

|

Hotop 4 Pieces Sublimation Socks Jigs Blanks Polyester Metal Insert... | Buy Now |

Hotop’s Sublimation Socks Jigs are crafted from durable aluminum alloy, designed to withstand deformation, rust, and breakage. This makes them ideal for both DIY sock printing and small-batch production. The set includes four jigs in two sizes, accommodating different adult sock fits and other flat items.

Each jig features a round top hole for easy wall hanging, helping to keep your workspace neat. Using the jigs is straightforward: print your design on transfer paper, straighten the socks on the jig, and apply heat with a press. Beyond socks, these jigs can also support cups, plates, and mouse pads, enhancing their versatility.

The sturdy design allows for repeated use without wear, making them a reliable choice for sublimation projects. Their construction and size variety help ensure consistent, professional results every time.

Best for: DIY crafters and small-business makers who need reusable jigs for sublimating socks and other flat items.

Pros:

- Made from durable aluminum alloy resisting deformation, rust, and breakage

- Includes two sizes with two jigs per size for different adult sock fits

- Round top hole enables easy wall hanging and compact storage

- Supports sublimation on socks and various other flat objects

Cons:

- Weight may be noticeable for portable or travel setups

- Functions only as sublimation/heat transfer jigs, not as standalone heat presses

- Requires compatible heat press and transfer materials for best results

Important: The product is designed to assist with heat transfer projects but does not replace a heat press machine itself.

Aluminum Sublimation Signs 6x12x0.018, 10-Pack

| Preview | Product | Price | |

|---|---|---|---|

|

Lesencen Sublimation Blanks Aluminum Metal Signs 0.018 inch thickness... | Buy Now |

These aluminum sublimation signs measure 6×12 inches with a sturdy 0.018-inch thickness. They come in a 10-pack, ideal for creating professional-quality nameplates, photo signs, or decorative pieces. The front surface is white with a protective film that you peel off before printing.

Printing is done through heat transfer at 170–200°C for 30–60 seconds using a heat press or sublimation device. The back side shows the natural aluminum finish. Each sign features rounded corners and a smooth, durable surface suitable for both indoor and outdoor applications.

This product is designed for straightforward sublimation printing, making it a practical choice for personalized signage and plaques. Its durable aluminum build ensures your prints stay vibrant in various environments.

Best for: DIY crafters and small businesses seeking durable, custom indoor and outdoor signs with a professional sublimation-ready surface.

Pros:

- Ready-to-use sublimation coating on the front simplifies printing.

- Versatile 6×12 inch size with rounded corners fits many signage needs.

- Durable aluminum construction suitable for indoor and outdoor use.

- Protective film ensures a clean printing surface.

Cons:

- The back side remains raw aluminum, which may limit design options.

- Requires access to a heat press or sublimation device operating at specified temperatures.

- Comes only in packs of 10, which might require additional purchasing for larger projects.

Important: Use only recommended heat transfer settings for best results and peel off the protective film before printing.

6061 Aluminum Sheet Metal Plates with Protective Film

| Preview | Product | Price | |

|---|---|---|---|

|

Tynulox 2PCS 6061 Aluminum Sheet Metal 1/4" x 6" x 12", Aluminum... | Buy Now |

6061 Aluminum Sheet Metal Plates with Protective Film offer durable and precise material for a variety of fabrication needs. Each plate measures 12″ x 6″ x 1/4″ and comes with a protective film on both sides. This film helps prevent scratches and bending during handling, ensuring a smooth, clean surface for your project.

The 6061 alloy is known for its excellent weldability and corrosion resistance. It maintains toughness and resists deformation even after processing. These plates are suitable for welding, stamping, and cutting, making them a versatile choice for many applications.

Securely packaged, these aluminum sheets are ideal for DIY crafts, model making, and decorative framing. Their smooth finish and consistent quality support precise fabrication and lasting performance.

Best for: DIY enthusiasts and hobbyists needing durable, weldable aluminum plates with protective film for scratch-resistant fabrication and precise cutting.

Pros:

- Excellent weldability and toughness of 6061 aluminum

- Protective film on both sides prevents scratches and bending

- Smooth, seamless surface ideal for welding, stamping, and cutting

Cons:

- Thickness may be heavier to handle for small, delicate projects

- Limited sheet size might require joining for larger builds

- Aluminum could be less cost-effective than some alternative metals

Important:

Description is based solely on the provided product details without external assumptions.

Factors to Consider When Choosing Aluminum Alloy for Heat Transfer

When you choose an aluminum alloy for heat transfer, you’ll weigh thermal conductivity against strength and weight tradeoffs to meet your design needs. Consider how corrosion resistance and machinability affect long-term performance and production efficiency, not just initial specs.

Balancing weight reduction gains with handling and tooling factors helps you pick an alloy that delivers reliable heat transfer with feasible manufacturing.

Thermal Conductivity Variance

Thermal conductivity varies across aluminum alloys, so you’ll want to compare how much each composition conducts heat before picking a material for heat transfer. You’ll notice pure aluminum conducts exceptionally well, with about 237 W/m·K, making it standout for rapid heat dissipation. However, alloys introduce tradeoffs.

Elements like silicon, magnesium, and copper can raise or lower overall conductivity, so your choice hinges on your balance between heat transfer and other properties. For example, 6061 alloy typically runs around 150–170 W/m·K, which is lower than pure aluminum but offers improved mechanical strength and formability. In heat sinks, diffusers, or similar components, opting for higher conductivity improves performance.

But you must weigh structural requirements and operating conditions to avoid unnecessary compromises.

Alloy Strength Tradeoffs

Alloy strength and heat transfer aren’t separate concerns; they influence each other, so you need to weigh them carefully for your heat-dissipation goals. In practice, higher strength often brings hardness and durability but can reduce thermal conductivity, limiting heat transfer efficiency.

Conversely, alloys with lower strength may excel thermally yet resist deformation under load, risking wear in demanding applications. The key is balancing mechanical resilience with thermal performance to meet your specific cooling needs. Strength gained through heat treatment or alloying can sometimes impede heat transfer, so you must assess whether the gains in rigidity justify any conductivity loss.

Selecting an alloy means understanding this compromise: align your choice with the required stress tolerance and the desired rate of heat removal. Clear tradeoffs guide you toward *ideal* heat-transfer performance.

Corrosion Resistance

Corrosion resistance hinges on composition and environment. You’ll choose alloys with higher zinc, magnesium, or silicon contents when you need tougher protection, since those elements boost resistance in many media. The natural oxide layer on aluminum is your first line of defense, so you’ll benefit from a surface that stays intact without coatings under normal use.

Alloys like 5052, 3003, and 6061 consistently show excellent corrosion resistance across several environments, making them reliable choices for heat-transfer applications. Be mindful that chloride-rich or acidic environments can erode protection if surface treatment is missing, so consider proper finishing. Anodizing creates a thicker, more durable oxide layer, markedly improving resistance in harsh conditions and extending service life.

Weight Reduction Gain

Balancing weight with performance starts by choosing aluminum alloys that keep heat transfer efficient without adding needless bulk. You’ll find that lower-density alloys like 6061 or 3003 considerably cut weight while preserving solid thermal conductivity, helping you design leaner heat paths. Thinner heatsinks or plates made from these lightweight alloys can still dissipate heat effectively, so you aren’t trading performance for a lighter build.

Opt for alloys with high strength-to-weight ratios to create durable heat-transfer components that are easier to handle and install, reducing installation effort and risk of damage. Lighter parts also boost mobility and lessen structural support needs in portable electronics. Finally, select alloying elements that optimize weight without compromising heat conduction and mechanical stability.

Machinability Factors

Machinability hinges on how easily an aluminum alloy can be cut, shaped, and finished without excessive tool wear. When you choose alloys like 6061 T6, you’ll notice magnesium and silicon help cutting and shaping feel smoother, reducing fatigue on your tools.

If you’re factoring in free-machining constituents such as lead or bismuth, you’ll get noticeably lower cutting forces and less wear, improving cycle times. The T6 temper’s solution heat-treatment and artificial aging also boost machinability, delivering cleaner finishes and easier chip formation.

Pay attention to microstructure: finer grains and well-distributed phases generally yield smoother machining and steadier feeds. Finally, consult machinability ratings, which reflect tool life and surface finish to guide comparisons among alloys for heat transfer applications.

Weldability Considerations

Weldability is a practical, performance-driven consideration when selecting aluminum alloys for heat transfer, because a weld that holds up under thermal cycling saves time and reduces costs. You’ll favor alloys with balanced composition, like 6061, which typically offers excellent weldability. Avoiding complex or high-alloy elements, such as those found in 2024, helps you prevent cracking and reduce the need for specialized welding techniques.

Remember to clean and remove oxide layers before welding, as this step directly strengthens the joint. Be aware that heat treatment states, such as T6 or T651, can influence weldability by shifting thermal and mechanical properties, so align your welding method accordingly. Choosing an alloy with good weldability minimizes porosity, hot cracking, and weak weld zones during fabrication.

Cost Versus Performance

Choosing the right aluminum alloy for heat transfer comes down to cost versus performance: higher-performance alloys like 6061-T6 deliver better thermal conductivity, but they cost more upfront. You weigh heat transfer efficiency against your budget, because the cost-benefit balance hinges on your application’s needs. Using premium alloys with better heat transfer properties can reduce the need for extra cooling components, potentially lowering overall system costs.

Conversely, cheaper alloys may have lower thermal conductivity, triggering higher cooling requirements and raising long-term operating expenses. To pick well, evaluate the specific thermal load, durability needs, and budget constraints for your project. Aim for the best performance-to-cost ratio by matching material properties to your heat transfer goals and lifecycle costs.

Temperature Stability

Temperature stability hinges on both alloy composition and heat treatment. You’ll want alloys like 6061 and 6061 T6 that keep structural integrity up to about 150°C to 200°C, making them solid choices for heat transfer. The stability you get depends on the specific alloying elements; certain compositions resist softening and deformation better under high heat.

If you increase copper or silicon content, you’ll enhance thermal conductivity while maintaining stability at elevated temperatures. The heat-treatment step, such as T6 tempering, boosts resistance to thermal expansion and helps keep dimensions steady during temperature changes. For high-temperature environments, you’ll find alloys are tested for a maximum operating temperature to prevent property loss and ensure reliable heat transfer performance.

Frequently Asked Questions

How Does Thermal Conductivity Influence Heat Sink Performance?

Thermal conductivity dictates how quickly heat moves from your device to the sink; higher k means faster spreading, thinner fins can work, and overall efficiency improves.

You’ll see lower temperatures and quieter operation with better-conducting materials.

Which Aluminum Alloy Offers Best Corrosion Resistance?

You’ll want 7075 or 5083? Actually, corrosion resistance leans toward 5052, 5083, and 6061 in many environments, but 5052 excels near seawater.

Choose 5083 for stronger general corrosion resistance and formability in harsh conditions.

Do Temper and Treatment Affect Heat Transfer Properties?

Yes, temper and heat treatment affect heat transfer in aluminum. They change conductivity pathways, grain structure, and surface roughness, which influence thermal performance.

You’ll see differences in steady-state cooling, transfer efficiency, and overall system response after processing.

How Important Is Density for Electronic Cooling Applications?

Density matters moderately for electronic cooling—you’ll want lower density materials to reduce overall weight, but thermal conductivity and heat capacity matter more for performance.

Choose alloys balancing density, conductivity, and mechanical stability for effective cooling.

What Trade-Offs Exist Between Weight and Thermal Efficiency?

Trade-offs exist: lighter weight can reduce inertia but sometimes lowers thermal capacity, while heavier alloys may boost heat spread. You’ll trade density for conductivity, aiming for a balance where a 10–20% weight change yields meaningful efficiency gains.

Conclusion

Conclusion: When selecting aluminum alloys for heat transfer, you’ll want a balance of thermal conductivity, strength, and diffusion capacity. For example, 6061 and 6063 offer good conductivity with formability, while incorporating 2024 or 7075 can boost rigidity where mounting stresses matter. These alloys are among the best aluminum alloys for heat transfer in 2026, providing reliable and efficient performance.

An interesting stat: aluminum’s thermal conductivity (~205 W/m·K) outpaces many steels, meaning thinner sections can still transfer heat efficiently. Prioritize alloys with low porosity and compatible coatings to maximize long-term performance. Choosing the right aluminum alloy is key to optimizing heat transfer in your applications.