10 Best Foam Cutting Machines of 2025 – Precision and Performance Reviewed

If you want precision and durability in 2025’s best foam cutting machines, consider options like the Proxxon Thermocut 115/E with its stable work surface.

Another great choice is the versatile 4 in 1 GOCHANGE set featuring digital voltage control, perfect for various tasks.

The Foam Cutter Machine with 10 nickel-chromium wires and air cooling offers fast cuts and excellent performance.

These tools provide adjustable heat settings, durable wires, and safety features designed to meet your craft or insulation needs.

Explore further to find the perfect fit for your projects and ensure you get the best foam cutting machine tailored to your requirements.

| Image | Name | Editor's Rating | Price |

|---|---|---|---|

|

Proxxon Thermocut 115/E Auto-CAD Hot Wir...

|

|

|

|

GOCHANGE 4 in 1 Foam Cutter Set with Dig...

|

|

|

|

RONGTER 4 in 1 Hot Wire Electric Foam Cu...

|

|

|

|

MINOVA Foam Cutter Machine, 220W Air Coo...

|

|

|

|

Ncepis Hot Foam CutterFoam Cutter Electr...

|

|

Key Takeaways

- Top foam cutters in 2025 feature precise temperature control for clean, detailed cuts on various foam densities and thicknesses. Machines like Proxxon Thermocut 115/E provide stable work surfaces and consistent wire temperatures for professional-grade accuracy.

- Digital voltage controllers and adjustable cutting angles enhance versatility and performance in leading foam cutting machines. Safety features such as overheat protection, LED indicators, and ergonomic designs are standard in the best 2025 models.

- Durable construction with replaceable nickel-chromium cutting wires ensures longevity and maintenance ease in top-rated foam cutters.

Proxxon Thermocut 115/E Auto-CAD Hot Wire Cutter with Large Table (Accessory for Thermocut Fence TA 300-37080)

| Preview | Product | Price | |

|---|---|---|---|

|

Proxxon Thermocut 115/E Auto-CAD Hot Wire Cutter with Large Table -... |

$126.66 |

Buy Now |

Achieve precise and clean foam cuts effortlessly with the Proxxon Thermocut 115/E Auto-CAD Hot Wire Cutter. This accessory enhances your Thermocut Fence TA 300-37080 by providing a stable and spacious aluminum Cobond working surface. It ensures smooth, accurate cuts by maintaining a consistent wire temperature around 360°F, which prevents rough edges and material damage.

Designed for both hobbyists and professionals, this cutter simplifies complex foam shaping tasks. The built-in grid and protractor allow for exact measurements and angled cuts, making your projects more precise and reducing material waste. Its solid aluminum overarm supports miter cuts, adding versatility to your toolkit.

The cutter’s lightweight design at just 7.9 pounds makes it easy to handle and transport, while the durable materials ensure long-lasting performance. Maintenance is straightforward: the robust construction minimizes wear, and the hot wire’s temperature control reduces the risk of overheating or wire breakage.

While the Proxxon Thermocut 115/E excels in foam cutting, it requires connection to the Thermocut Fence TA 300-37080, limiting its standalone use. It is specifically optimized for foam, so other materials may not yield the same quality results.

Best for: hobbyists and professionals seeking precise and clean foam cutting with a versatile, easy-to-use hot wire cutter accessory.

What We Like:

- Consistent 360°F wire temperature ensures smooth, accurate cuts

- Large aluminum Cobond surface with grid and protractor for precise measuring

- Lightweight and portable at 7.9 pounds for easy handling

- Solid aluminum overarm supports miter cuts for enhanced versatility

Specification:

| Feature | Details |

|---|---|

| Manufacturer | Proxxon |

| Dimensions | Large working surface (exact size not specified) |

| Weight | 7.9 lb (3.6 kg) |

| Material | Aluminum Cobond, solid aluminum overarm |

| Power Supply | 115V AC |

| Compatible Accessory | Thermocut Fence TA 300-37080 |

4 in 1 GOCHANGE Electric Foam Cutter Set with Digital Voltage Controller

| Preview | Product | Price | |

|---|---|---|---|

|

4 in 1 Foam Cutter Set with Digital Voltage Controller, GOCHANGE... |

$26.99 |

Buy Now |

The 4 in 1 GOCHANGE Electric Foam Cutter Set offers precise and adaptable cutting for various foam projects. Its digital voltage controller lets you easily adjust the heat to match different foam densities, ensuring smooth, clean cuts without damaging the material. This control helps eliminate rough edges and uneven surfaces, making your work look professional.

Designed to heat rapidly, the cutter reaches temperatures between 160℃ and 280℃ within seconds, allowing you to work efficiently without waiting. The stainless steel construction provides durability, while the lightweight design reduces fatigue during prolonged use. These features combine to make the tool comfortable and reliable for detailed foam shaping.

For maintenance, it’s important to allow the cutter to rest after 30 minutes of continuous use to prevent overheating. Cleaning the heating needle regularly helps avoid oxidation, maintaining consistent performance over time. This care routine extends the tool’s lifespan and ensures it stays ready for your next project.

Ideal for artists, crafters, and model makers, this versatile foam cutter supports intricate designs and a variety of angles. Whether you’re crafting delicate shapes or cutting thick foam, it adapts to your needs with precision and ease.

Best for: Hobbyists and professionals seeking precise, adjustable foam cutting tools for art, crafts, modeling, and DIY projects.

What We Like:

- Digital voltage control for tailored cutting on different foam types

- Rapid heating for fast, clean cuts without debris

- Durable stainless steel and lightweight for comfortable use

- Supports complex shapes with versatile blade options

- Maintenance tips ensure long-lasting performance

Specification:

| Feature | Details |

|---|---|

| Manufacturer | GOCHANGE |

| Dimensions | Not specified |

| Weight | Lightweight design |

| Material | Stainless steel |

| Temperature Range | 160℃ to 280℃ |

| Voltage Control | Digital adjustable |

4 in 1 Hot Wire Electric Foam Cutter Kit with Case (Toolbox Orange)

| Preview | Product | Price | |

|---|---|---|---|

|

RONGTER 4 in 1 Hot Wire Electric Foam Cutter Kit, Styrofoam Cutting... |

$45.99 |

Buy Now |

The 4 in 1 Hot Wire Electric Foam Cutter Kit with Case (Toolbox Orange) transforms foam cutting into a smooth, precise task. Its quick-heating 15W power ensures you spend less time waiting and more time crafting. The hot wire reaches temperatures up to 842℉, cutting through foam cleanly with sealed edges to prevent fraying or residue.

Designed with versatility in mind, this kit includes four distinct blade types and five replacement wires, allowing you to tackle various foam shapes and densities. The sturdy toolbox case keeps everything organized and easy to carry. The cutter’s ambidextrous grip and metal rest provide comfortable handling and safe placement when not in use.

Maintenance is straightforward; replacement wires are readily available, and the overheat protection feature prevents damage from excessive use. However, this tool is best suited for foam materials and is not effective on plastic, high-density sponges, memory foam, or nylon fabric. Care is needed when handling the heated elements and power supply to ensure safety.

This electric foam cutter is ideal for hobbyists, model makers, and professionals who require a reliable, fast-heating tool for clean foam work. Its design balances precision, safety, and convenience, making it a practical addition to any foam crafting setup.

Best for: Hobbyists and professionals looking for a versatile, quick-heating foam cutting tool with precise control and safe operation.

What We Like:

- Rapid, even heating for smooth, clean cuts without debris

- Multiple blade types and replacement wires included

- Sturdy, portable carrying case for organized storage

- Safety features like overheat protection and metal rest

- Comfortable ambidextrous grip for extended use

Specification:

| Feature | Details |

|---|---|

| Manufacturer | Not specified |

| Power | 15W |

| Max Temperature | 842℉ (450℃) |

| Weight | 3.41 lb (1.55 kg) |

| Color | Toolbox Orange |

| Included Blades | 4 types |

| Replacement Wires | 5 wires |

| Case | Sturdy toolbox case |

Foam Cutter Machine with 10 Cutting Wires and Air Cooling System

| Preview | Product | Price | |

|---|---|---|---|

|

MINOVA Foam Cutter Machine, 220W Air Cooling System, Electric Hot Wire... |

$189.99 |

Buy Now |

Experience hassle-free insulation cutting with the Foam Cutter Machine featuring 10 cutting wires and an efficient air cooling system. This tool is designed to simplify your workflow by enabling fast, precise cuts through various foam materials like PE, EPS, XPS, and EVA. Its lightweight design makes it easy to handle, reducing fatigue during extended use.

The MINOVA Model 2.1’s air-cooled 220W power supply offers a safer and more durable alternative to traditional transformers. This system prevents overheating, ensuring continuous operation without frequent pauses for cooling. The included nickel-chromium copper alloy wires resist deformation, maintaining consistent cutting quality over time.

Maintenance is straightforward, with easily replaceable cutting wires to keep performance steady. The stopping bar allows for clean cuts up to 13 inches deep, catering to a range of insulation thicknesses. Versatility is key—this machine supports vertical and scaffolding setups, improving safety and accessibility on job sites.

While the cutter excels in precision and ease of use, heavy users may find the limited number of cutting wires restricts continuous work without replacement. Additionally, its maximum cutting depth may not suit all insulation tasks, and the air-cooled system can be noisier compared to transformer-based models.

Best for: Professionals and contractors needing precise, efficient cutting of insulation foam in construction or manufacturing environments.

What We Like:

- Lightweight design enhances user comfort and control

- Durable nickel-chromium copper alloy wires resist deformation

- Air-cooled power supply prevents overheating during extended use

- Supports vertical and scaffolding setups for flexible operation

Specification:

| Feature | Details |

|---|---|

| Manufacturer | MINOVA |

| Model | 2.1 |

| Power Supply | 220W Air Cooled |

| Cutting Wires | 10 Nickel-Chromium Copper Alloy |

| Maximum Cutting Depth | 13 inches (33 cm) |

| Compatible Materials | PE, EPS, XPS, EVA Foam |

| Weight | Lightweight (exact weight not specified) |

Hot Foam Cutter Electric Cutting Machine Pen Tool Kit with Digital Voltage Controller

| Preview | Product | Price | |

|---|---|---|---|

|

Hot Foam CutterFoam Cutter Electric Cutting Machine Pen Tools Kit with... |

$25.99 |

Buy Now |

Experience precise and clean cuts with the Hot Foam Cutter Electric Cutting Machine Pen Tool Kit. Designed for smooth and debris-free foam cutting, it heats rapidly to 100℃, allowing you to work efficiently without waiting. The digital voltage controller ensures you get the exact temperature needed, adapting seamlessly to various foam types and thicknesses.

This versatile kit includes multiple wand styles and a bow hot blade, giving you flexibility for different cutting angles and shapes. Its durable stainless steel and plastic construction provide longevity and reliable performance, while built-in overheat protection keeps the tool safe during extended use.

Maintenance is straightforward but essential for optimal results. Regular cleaning of the cutting tips prevents residue buildup and preserves sharpness. To avoid overheating, it is recommended to pause every 30 minutes, ensuring consistent cutting quality and extending the tool’s lifespan.

Ideal for artists, hobbyists, and professionals, this foam cutter enhances craft projects, model making, and commercial applications where accuracy matters. Its thoughtful design balances power and safety, making it a dependable tool for detailed foam work.

Best for: Hobbyists, model makers, and professionals who require precise and adaptable foam cutting tools for creative and commercial projects.

What We Like:

- Rapid heating to 100℃ in under 15 seconds for quick workflow

- Digital voltage controller for precise temperature adjustment

- Multiple cutting tips and bow blade for versatile applications

- Durable materials with built-in overheat protection

- Easy maintenance with regular tip cleaning recommended

Specification:

| Feature | Description |

|---|---|

| Manufacturer | Not specified |

| Dimensions | Not specified |

| Weight | Not specified |

| Material | Stainless steel, plastic |

| Color Options | Not specified |

Electric Hot Knife Kit with 5 Blades for Foam Cutting and Sculpting

| Preview | Product | Price | |

|---|---|---|---|

|

NLBFOU Electric Hot Knife Kit for Grooving/Sculpting/Cutting (5... |

$118.99 |

Buy Now |

Experience precise foam cutting and sculpting like never before with the Electric Hot Knife Kit. This versatile tool is designed to help you create clean grooves and custom shapes effortlessly. Its bendable 12-inch blade allows you to make circular, square, V, triangular, and unique cuts, ideal for wiring and plumbing work in insulation foam.

The kit’s air-cooled 200W system features dual fans, enabling continuous use for up to 120 minutes without overheating. This means you can maintain steady productivity without frequent breaks. The included grooving platform and steel ruler ensure accuracy, while the carrying case makes transport and storage simple.

Maintenance is straightforward thanks to the durable blades and robust design. The kit is easy to assemble and built for repeated use on foam and similar soft materials. However, it is not suited for harder substances, and its 110-120V power requirement may need an adapter in some regions.

With this hot knife set, you gain a reliable tool that enhances your foam cutting and sculpting tasks. Whether for home projects or professional use, it streamlines your work and opens up creative possibilities.

Best for: DIY enthusiasts, contractors, and hobbyists needing precise and versatile foam cutting tools for insulation, wiring, plumbing, and decorative projects.

What We Like:

- Bendable 12-inch blade for diverse custom cuts

- Air-cooled dual fans allow 120 minutes of continuous use

- Includes grooving platform, steel ruler, and portable carrying case

- Easy assembly and durable construction

Specification:

| Feature | Details |

|---|---|

| Manufacturer | NLBFOU |

| Power | 200W |

| Blade Length | 12 inches |

| Cooling System | Air-cooled with dual fans |

| Voltage | 110-120V |

| Included Accessories | 5 blades, grooving platform, steel ruler, carrying case |

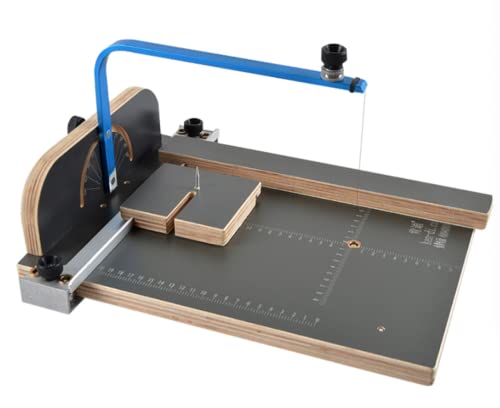

Hot Wire Foam Cutter Table for Foam Model Building

| Preview | Product | Price | |

|---|---|---|---|

|

Hot Wire Foam Cutter Table, Adjustable Foam Cutting Machine, Styrofoam... |

$87.37 |

Buy Now |

Discover the precision and ease the Hot Wire Foam Cutter Table brings to foam model building. Its spacious 11 x 15-inch work area allows you to handle larger foam pieces effortlessly, making detailed crafting more manageable. The adjustable design ensures you can set cutting angles from 0 to 60 degrees on either side, giving you flexibility for various project needs.

This tool’s thin 0.18 mm wire glides through soft foam smoothly, minimizing debris and improving the cleanliness of cuts. A multi-angle guide combined with a centering pin ensures your cuts are accurate and consistent, whether you are making straight lines or smooth curves. This precision supports intricate model building with less frustration.

Constructed with a lightweight yet sturdy wooden frame, the cutter weighs just 5.89 pounds, making it easy to move and store. Powered by a 10V, 1.8A adapter, it maintains steady heat for reliable performance. Routine maintenance is straightforward, focusing mostly on replacing the thin wire when worn to keep cutting quality high.

While ideal for soft foam materials, this cutter is not suited for harder or denser foam types. The wire height of 145 mm may limit cutting very thick blocks, and the wooden frame, though durable, may not match the longevity of metal alternatives.

Best for: hobbyists and model builders who require precise, clean cuts on soft foam materials for detailed crafting projects.

What We Like:

- Large work surface accommodates bigger foam pieces.

- Adjustable cutting angles enhance versatility.

- Thin wire produces smooth, debris-free cuts.

- Lightweight wooden frame balances durability and portability.

- Clear surface markings aid in accurate cutting.

Specification:

| Feature | Details |

|---|---|

| Manufacturer | Not specified |

| Dimensions | 11 x 15 inches |

| Weight | 5.89 lb (2.67 kg) |

| Material | Wood frame |

| Wire Thickness | 0.18 mm |

| Power Adapter | 10V, 1.8A |

| Max Wire Height | 145 mm |

Desktop hot wire foam cutting machine

| Preview | Product | Price | |

|---|---|---|---|

|

Desktop hot wire foam cutting machine | $799.00 | Buy Now |

Discover the precision and ease of the desktop hot wire foam cutting machine, designed to transform your foam-cutting tasks. This compact tool ensures clean, accurate cuts on medium and low-density foams without demanding advanced skills. Its electric hot wire heats efficiently at 110V and 160W, making it ideal for materials like EPE pearl cotton, EPS foam board, and filter cotton.

The machine’s adjustable ceramic insulating assembly enables cutting heights between 30 and 600mm, while the hot wire angle tilts from 45 to 90 degrees. This flexibility allows you to create straight edges or intricate shapes effortlessly. With a positioning ruler that adjusts up to 450mm, you maintain control over your project dimensions with precision.

Maintenance is straightforward due to its simple design. The ceramic insulation helps prevent heat damage, prolonging the life of the hot wire and ensuring consistent performance. Its mess-free operation means less cleanup and more focus on your creative process.

This desktop foam cutter is perfect for hobbyists and small-scale professionals who need a reliable and user-friendly tool for detailed foam shaping. It streamlines cutting tasks, reducing errors and material waste.

Best for: Hobbyists and small-scale professionals seeking an easy-to-use, precise tool for cutting medium and low-density foam materials.

What We Like:

- Adjustable cutting height and hot wire angle for versatile shapes

- Simple operation requiring no special training

- Clean, precise cuts with minimal mess

- Durable ceramic insulating assembly for extended use

Specification:

| Feature | Details |

|---|---|

| Manufacturer | Not specified |

| Power | 110V, 160W |

| Cutting Height Range | 30–600 mm |

| Hot Wire Angle Range | 45–90 degrees |

| Positioning Ruler Length | Up to 450 mm |

| Suitable Materials | Medium and low-density foams |

24W Hot Wire Foam Cutter Table Precision DIY Craft Tool

| Preview | Product | Price | |

|---|---|---|---|

|

RONGTER 24W Hot Wire Foam Cutter Table, Precision DIY Craft Tool with... |

$89.99 |

Buy Now |

The 24W Hot Wire Foam Cutter Table is designed to make foam cutting projects easier and more precise. Its adjustable power settings let you control the temperature, helping you achieve clean, accurate cuts on Styrofoam, foam board, and similar materials. This flexibility solves common issues like uneven edges and rough finishes, improving your overall crafting experience.

The cutter features a sturdy 11.8 x 15.7-inch table that supports foam up to 12 inches thick and 7 inches high. This ample workspace allows you to handle larger projects without hassle. Its lightweight design, weighing only 8.8 pounds, makes it easy to move and store, perfect for hobbyists and DIY enthusiasts with limited space.

Maintenance is straightforward, though the 0.2mm heating wire may wear out and need replacement over time. This is typical for hot wire cutters but should be considered for long-term use. The device is specialized for foam materials and should not be used with harder substances, ensuring safety and optimal performance.

Overall, this hot wire foam cutter combines precision, versatility, and ease of use. It’s especially beneficial for model makers, prop builders, and craft hobbyists looking for a reliable tool to bring detailed foam designs to life.

Best for: hobbyists and DIY enthusiasts seeking a precise, adjustable foam cutting tool for crafting and modeling projects.

What We Like:

- Adjustable power for precise temperature control

- Large cutting surface supports thick foam pieces

- Lightweight and portable design

- Durable wire with a generous length for extended use

- Easy to maintain with replaceable heating wire

Specification:

| Feature | Details |

|---|---|

| Manufacturer | RONGTER |

| Dimensions | 11.8 x 15.7 inches |

| Weight | 8.8 lbs |

| Heating Wire | 0.2mm diameter, 10 ft long |

| Max Temperature | 788°F (approx. 420°C) |

| Material | Metal frame, wire cutter |

4 in 1 Hot Wire Electric Foam Cutter Kit with Case (15W/6V)

| Preview | Product | Price | |

|---|---|---|---|

|

RONGTER 4 in 1 Hot Wire Electric Foam Cutter Kit, Styrofoam Cutting... |

$45.99 |

Buy Now |

Experience precision in every cut with the 4 in 1 Hot Wire Electric Foam Cutter Kit. This tool is designed to tackle detailed foam shaping effortlessly. Its quick and even heating system ensures your cuts are smooth and free of debris, making your projects cleaner and more professional.

The kit’s versatility shines with four blade options and five replacement wires, allowing you to switch tools depending on your project needs. All components are neatly stored in a sturdy case for easy transport and organization. The metal support frame stabilizes your cutting, while the LED safety light improves visibility and safety during use.

Maintenance is straightforward, requiring minimal effort to keep the cutter in optimal condition. Just handle the hot wire carefully and replace it when worn to maintain cutting performance. This cutter is ideal for foam boards, KT boards, and similar materials but is not suited for plastics or dense sponges.

Perfect for hobbyists and professionals, this kit enhances creative projects with precision and reliability. Its focused design improves workflow and reduces material waste, making foam crafting more efficient and enjoyable.

Best for: Hobbyists, model makers, and professionals needing a versatile and precise foam cutting tool.

What We Like:

- Fast, even heating for clean, precise cuts

- Multiple blade types and replacement wires included

- Durable carrying case for easy storage and transport

- Metal support frame and LED safety light for stability and safety

- Simple maintenance for long-lasting use

Specification:

| Feature | Details |

|---|---|

| Manufacturer | Not specified |

| Power | 15W |

| Voltage | 6V |

| Heating Tips | U-shaped, F-shaped |

| Accessories | 4 blades, 5 replacement wires |

| Case | Durable carrying case |

| Dimensions | Not specified |

| Weight | Not specified |

Factors to Consider When Choosing a Foam Cutting Machine

When choosing a foam cutting machine, you’ll want to focus on cutting precision and the power options that fit your needs. Consider the types of wires or blades, as well as the size and material of the worktable.

Don’t forget to check the safety features to keep your workspace secure.

Cutting Precision Requirements

Because cutting precision determines the quality of your foam projects, you’ll want a machine that offers accurate measurements and fine control. Look for features like printed grids and protractors to guarantee your cuts are exact. Adjustable cutting angles and depth settings help you tailor the machine to different foam types and project needs.

The wire’s construction, often nickel-chromium copper alloy, impacts durability and the smoothness of your cuts. Machines that reach wire temperatures up to 842°F allow for cleaner cuts and better handling of intricate shapes. Consider whether the machine can perform specialized cuts like miters or bevels, as these enhance your ability to create professional-grade projects.

Prioritizing these precision elements will elevate your foam cutting results dramatically.

Power and Voltage Options

Choosing the right power and voltage options can make a big difference in how efficiently your foam cutting machine performs. Higher wattage, like 220W compared to 160W, heats the wire faster and cuts foam more quickly. You’ll want a machine compatible with your local voltage—usually between 100V and 240V—to guarantee safe, reliable operation.

Look for models with digital voltage controllers; they let you adjust settings based on foam density, improving cutting precision and efficiency. Safety features like overheat protection not only keep you safe but also extend the machine’s lifespan during long sessions. While not the focus here, remember that the heating wire’s material and thickness also affect how well your machine cuts and holds heat.

Wire and Blade Types

Although power and voltage impact performance, the wire and blade types you pick will directly shape your cutting precision and the range of foam you can handle. For wire, nickel-chromium copper alloy stands out due to its durability and resistance to deformation, ensuring consistent cuts. Thinner wires excel at intricate, detailed work, while thicker ones speed up cutting larger foam sections.

When it comes to blades, options like U-shaped, F-shaped, and straight designs offer different cutting styles and depths, letting you tailor your approach to the project. Pay attention to the heating element’s temperature, too—higher settings (up to 842°F/450°C) cut denser foam more cleanly with less debris. Adjustable cutting angles and depths further enhance precision, giving you the flexibility to create complex shapes effortlessly.

Worktable Size and Material

When you select a foam cutting machine, the worktable size plays a key role in handling your projects effectively. Larger tables, like those around 15 x 11 inches, give you more space to move and manipulate foam easily, especially with bigger pieces. Consider the material too—durable options like aluminum or wood provide stability and guarantee your machine lasts longer.

An adjustable worktable height can boost your comfort and help you achieve precise cuts by letting you access different angles smoothly. Some machines even have printed grids and protractors on the table, which make measuring and cutting more accurate. By focusing on these factors, you’ll find a foam cutting machine that fits your project size and offers reliable, precise performance.

Safety Features Included

Because foam cutting involves heated tools and precise movements, you’ll want to prioritize safety features that protect both you and your workspace. Look for machines with overheat protection to prevent dangerous temperature buildup during extended use. Touch buttons and LED indicators improve visibility and reduce the risk of accidental burns.

Adjustable height and angle settings help you maintain control, ensuring safer, more precise cuts. Many models come with metal support frames for resting heated tips safely, minimizing burns and surface damage. Also, choose user-friendly designs that allow easy cleaning and maintenance, like using a cleaning pen after each session.

These features not only enhance safety but also extend your machine’s lifespan, making your foam cutting experience both secure and efficient.

Versatility and Applications

Since foam cutting projects vary widely, you’ll want a machine that handles different foam densities and shapes with ease. Look for a cutter compatible with low to medium-density materials like EPS, EPE, and XPS, so you can tackle diverse tasks. Versatility also means creating straight edges, curves, and intricate designs for artistic or model-making projects.

Adjustable temperature settings and interchangeable cutting tips let you customize your tool to match foam types and project needs perfectly. Machines offering multiple functions—cutting, grooving, sculpting—expand your creative possibilities, whether for crafts, commercial art, or education.

Finally, consider a compact, portable design to easily move and store your machine, boosting usability across various workspaces without sacrificing performance.

Maintenance and Durability

Though choosing the right foam cutting machine is important, ensuring it stays in top condition requires attention to maintenance and durability. Look for machines made from high-quality stainless steel and durable plastics; these materials resist wear and last longer.

Regularly clean heating elements to prevent oxidation, which keeps cutting performance sharp. Machines with overheat protection safeguard against damage during extended use, boosting both safety and lifespan. Also, check if replacement parts like cutting wires and tips are readily available—this saves you from buying a new unit prematurely.

Finally, opt for user-friendly designs that simplify maintenance and repairs, so you can keep your machine running smoothly without hassle. Prioritizing these factors helps you get the most from your foam cutting investment.

Frequently Asked Questions

How Do I Maintain and Clean a Foam Cutting Machine?

You should regularly clean the blade and machine surface, remove foam debris, and lubricate moving parts. Always unplug it first, check for wear, and follow the manufacturer’s maintenance guide to keep your foam cutter running smoothly.

Routine maintenance helps prevent damage and ensures precise cuts. Pay special attention to the blade condition and replace it if it becomes dull or damaged. Keeping the machine clean and well-lubricated extends its lifespan and performance.

Are Foam Cutting Machines Safe for Beginners?

Yes, foam cutting machines are safe for beginners if you follow instructions carefully and use protective gear. Start with simple projects, keep your workspace tidy, and never rush to guarantee safe, precise cuts every time.

What Types of Foam Materials Can These Machines Cut?

You can slice through everything from soft craft foam to dense upholstery foam—basically, these machines treat foam like a hot knife through butter, no foam left uncut.

Just don’t try slicing your sandwich with it!

Can Foam Cutters Be Used for Other Crafts Besides Foam?

Yes, you can use foam cutters for other crafts like cutting fabric, paper, and thin plastics. Just make certain the machine’s blade suits your material to get clean cuts and avoid damaging your projects or the cutter itself.

Using the appropriate blade ensures precision and safety during crafting. Always test on a scrap piece first to confirm compatibility.

What Is the Typical Warranty Period for Foam Cutting Machines?

You’ll typically get a 1-3 year warranty on foam cutting machines. Notably, 70% of users find warranties essential for peace of mind, especially since these tools endure heavy use and occasional maintenance needs.

Having a warranty helps cover repairs or replacements, reducing unexpected expenses. It’s a key factor to consider when purchasing a foam cutting machine.

Conclusion

When choosing a foam cutting machine, you want precision and ease. Did you know that using the right cutter can improve your project accuracy by up to 30%? Whether you pick a hot wire cutter with digital controls or a versatile 4-in-1 set, the right tool makes all the difference.

Keep your needs and budget in mind. You’ll create flawless foam designs faster and cleaner than ever before. Investing in the best foam cutting machine ensures you get the precision and performance required for top-quality results.