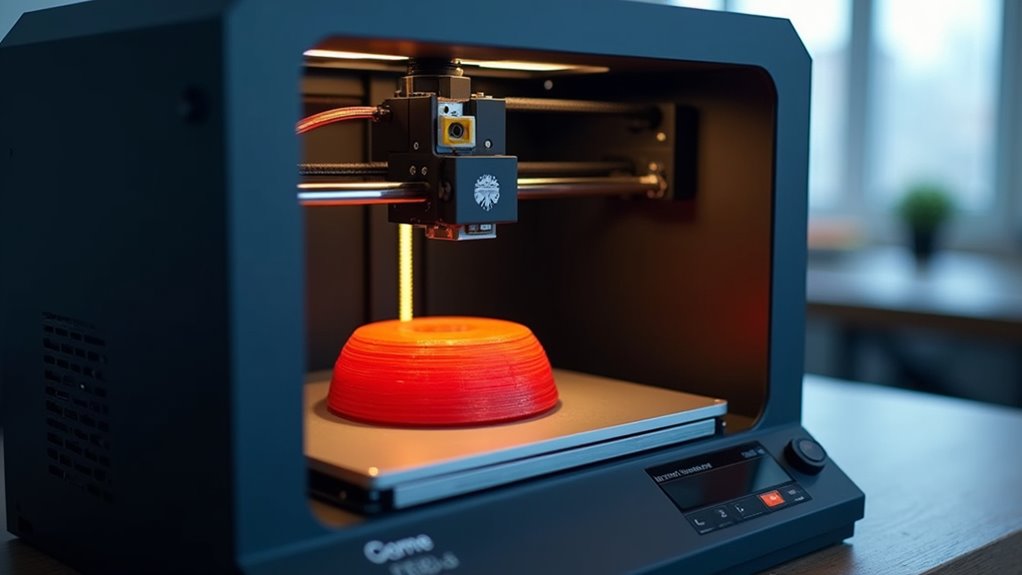

The 5 Best Printers for PETG Filament in 2025 – Reliable and High-Quality Picks

If you want reliable, high-quality 3D printers for PETG in 2025, consider the Creality Ender 3 V3 Plus with a large build volume and auto-leveling, or the versatile Bambu Lab P1S Combo that supports multi-material printing.

The compact Bambu Lab A1 Mini offers precision and quiet operation, while the FLASHFORGE AD5X excels with multi-color printing at high speeds.

For general use, the Brother INKvestment 1365 is great too.

Keep exploring to find the perfect fit for your printing needs.

| Image | Name | Editor's Rating | Price |

|---|---|---|---|

|

Creality Ender 3 V3 Plus 3D Printer, Cor...

|

|

|

|

Brother INKvestment 1365 Wireless Color ...

|

|

|

|

BAMBULAB Bambu Lab P1S Combo, P1S 3D Pri...

|

|

|

|

BAMBULAB Bambu Lab A1 Mini 3D Printer, S...

|

|

|

|

FLASHFORGE AD5X Multi-Color 3D Printer w...

|

|

Creality Ender 3 V3 Plus 3D Printer with Auto Leveling and Large Print Size

| Preview | Product | Price | |

|---|---|---|---|

|

Creality Ender 3 V3 Plus 3D Printer, CoreXZ 600mm/s High-Speed Auto... |

$397.98 |

Buy Now |

The Creality Ender 3 V3 Plus is designed for large-scale 3D printing projects. It features a spacious build volume of 300mm x 300mm x 330mm, allowing you to create sizable PETG parts with ease. The printer’s rigid triangular support rods and dual motors reduce wobbling, delivering precise and clean layers.

This model includes a direct drive extruder combined with a tri-metal unicorn nozzle, ensuring smooth and clog-free PETG filament extrusion. Auto-leveling with one-tap calibration makes setup straightforward and efficient. Overall, the printer balances robust functionality and user-friendly design.

Best for: hobbyists and small businesses seeking a reliable 3D printer for large, accurate PETG parts with minimal setup.

Pros:

- Large build volume suitable for bigger projects

- Dual motors and triangular support rods minimize print wobble

- Direct drive extruder with tri-metal nozzle ensures smooth extrusion

Cons:

- May be less portable due to weight

- Customer rating indicates some areas could improve

- Popularity ranks below top industrial 3D printers

Brother INKvestment 1365 Wireless Color Inkjet All-in-One Printer (MFC-J1365DW)

| Preview | Product | Price | |

|---|---|---|---|

|

Brother INKvestment 1365 Wireless Color Inkjet All-in-One Printer with... |

$159.99 |

Buy Now |

The Brother INKvestment 1365 Wireless Color Inkjet All-in-One Printer (MFC-J1365DW) delivers sharp, high-resolution color printing with a resolution of up to 1,200 x 6,000 dpi. It supports wireless connectivity through Wi-Fi Direct and USB, allowing you to print easily from multiple devices. The printer also features an automatic duplex function for double-sided printing, which helps save paper.

With a 150-sheet paper tray and a 20-page automatic document feeder (ADF), this all-in-one printer enhances your productivity by handling multi-page tasks efficiently. The compact design includes a 1.8” color display for straightforward navigation. Managing print jobs is simple through the Brother Mobile Connect app, and the ink subscription service ensures you won’t run out of ink unexpectedly.

Best for: individuals and small offices needing a high-resolution color inkjet printer with wireless features and cost-effective ink management.

Pros:

- Crisp print quality with up to 1,200 x 6,000 dpi resolution

- Automatic duplex printing and convenient 20-page ADF

- Wireless printing via Wi-Fi Direct and mobile app support

Cons:

- Color print speed may be slower at 9 ppm compared to black

- Paper capacity might require frequent refills during heavy use

- Smaller 1.8” display could limit ease of navigation for some users

Bambu Lab P1S Combo 3D Printer with AMS and Multi-Color Support

| Preview | Product | Price | |

|---|---|---|---|

|

Bambu Lab P1S Combo, P1S 3D Printer and AMS, Support Up to 16... |

$599.00 |

Buy Now |

The Bambu Lab P1S Combo is a fast and versatile 3D printer designed to handle multiple materials, including PETG, PLA, and TPU. It supports up to 16 colors, allowing for vibrant and detailed multi-color prints. Its fully enclosed design helps maintain print quality, especially with advanced filaments.

With speeds up to 500mm/s and automatic bed leveling, setup is quick and user-friendly. The printer’s precision and efficiency make it suitable for both beginners and experienced users. It delivers consistent results across various filament types, ensuring reliable performance.

Best for: users seeking a high-speed, multi-material 3D printer with multi-color capabilities and easy setup.

Pros:

- Supports up to 16 colors and multiple filament types.

- High-speed printing at 500mm/s with smooth acceleration.

- Fully enclosed design with automatic bed leveling for quality prints.

Cons:

- May not be ideal for carbon or glass fiber reinforced polymers.

- Advanced features might require some prior 3D printing experience.

- Larger print volume could be challenging for absolute beginners.

Bambu Lab A1 Mini 3D Printer with Multi-Color Printing and Auto Calibration

| Preview | Product | Price | |

|---|---|---|---|

|

Bambu Lab A1 Mini 3D Printer, Support Multi-Color 3D Printing, Set Up... |

$219.99 |

Buy Now |

The Bambu Lab A1 Mini 3D Printer offers high-speed precision with acceleration up to 10,000 mm/s². It features Active Flow Rate Compensation to ensure consistent, accurate results. This compact printer supports multi-color printing with the optional AMS lite, enabling vibrant and detailed designs.

Setup is quick, taking about 20 minutes, and the intuitive touchscreen makes operation straightforward. Full-auto calibration guarantees optimal performance each time you print. The printer runs quietly at ≤48 dB with active noise cancellation, improving the user experience in any environment.

Maintenance is simple with the 1-Clip quick swap nozzle, keeping your workflow smooth and efficient. Its design balances functionality and ease of use, making it suitable for a range of PETG projects.

Best for: hobbyists and professionals looking for fast, precise multi-color 3D printing with easy setup and quiet operation.

Pros:

- High-speed precision with acceleration up to 10,000 mm/s²

- Multi-color printing capability via AMS lite accessory

- User-friendly touchscreen and full-auto calibration

- Quiet printing with active noise cancellation at ≤48 dB

Cons:

- Multi-color printing requires the additional AMS lite accessory

- Warranty details are not clearly outlined upfront

- Build volume may limit larger-scale projects

FLASHFORGE AD5X Multi-Color 3D Printer with High Speed and Auto Leveling

| Preview | Product | Price | |

|---|---|---|---|

|

FLASHFORGE AD5X Multi-Color 3D Printer with IFS, 600mm/s High Speed,... |

$499.00 |

Buy Now |

The Flashforge AD5X Multi-Color 3D Printer offers simultaneous printing with up to four colors, perfect for creating vibrant, multi-material PETG models. Its Intelligent Filament System supports diverse materials like PETG-CF, flexible TPU, and carbon fiber filaments for versatile projects. The all-metal CoreXY frame ensures high stability and precision at speeds reaching 600mm/s.

This printer features a 300°C nozzle and user-friendly functions such as one-click auto leveling and automatic filament loading, streamlining your print setup. Remote management and real-time monitoring options allow you to stay in control of your prints from anywhere, enhancing convenience and efficiency.

Best for: professionals and enthusiasts who require high-speed, multi-color 3D printing with advanced material compatibility and remote operation.

Pros:

- Four-color simultaneous printing with Intelligent Filament System

- High-speed printing up to 600mm/s on a stable CoreXY chassis

- One-click auto leveling and filament auto-loading for ease of use

- Remote monitoring supports real-time print management

Cons:

- May require an additional camera kit for full real-time monitoring

- Could be less portable due to its sturdy build

- Advanced materials support might increase setup complexity

Factors to Consider When Choosing a Printer for PETG

When choosing a printer for PETG, you’ll want to check the print bed temperature range and make sure it can handle higher heat. Look for extruder compatibility and an enclosed build chamber to improve layer adhesion and print quality.

Also, consider the printer’s speed capabilities to balance detail with efficiency.

Print Bed Temperature Range

Achieving strong adhesion and minimizing warping with PETG filament depends heavily on maintaining the right print bed temperature. You’ll want a heated bed that consistently stays between 70°C and 80°C, as this range guarantees proper adhesion and reduces the risk of warping during printing.

If the bed temperature falls below 70°C, your print may lift or warp as it cools, leading to imperfections. To boost adhesion even more, many users apply a thin layer of glue stick or hairspray on the bed. Consistency is key—fluctuations in temperature can weaken layer bonding and harm the final print quality.

When choosing a printer for PETG, prioritize one with a reliable heated bed that can maintain this temperature range throughout the entire print process.

Extruder Type Compatibility

Maintaining the right bed temperature sets the stage for successful PETG printing, but your extruder also plays a key role in handling this material effectively. You’ll want a direct drive extruder since it offers better control over filament feeding and reduces clogs. Confirm the hotend reaches at least 230°C, as PETG needs higher temperatures than PLA.

An all-metal hotend is essential to withstand the heat without melting. Also, look for an extruder with a strong filament grip to prevent slippage and guarantee smooth, consistent flow. Using a nozzle size of 0.4mm or larger is smart—it cuts down on clogging and speeds up printing.

Choosing the right extruder setup will help you get reliable, high-quality PETG prints every time.

Enclosed Build Chamber

Since printing with PETG demands stable conditions, choosing a printer with an enclosed build chamber can make a significant difference. The enclosed environment maintains a consistent temperature, which helps reduce warping and print failures. It also shields your print from drafts and fluctuating ambient temperatures that could distort the layers.

This stability means you get more reliable and successful prints every time. Additionally, an enclosed chamber helps control humidity, a key factor since PETG is hygroscopic and sensitive to moisture. It also minimizes fumes emitted during printing, enhancing safety and comfort.

Layer Adhesion Quality

When you print with PETG, ensuring strong layer adhesion is key to producing durable, high-quality parts. You’ll want a printer that maintains nozzle temperatures between 230°C and 250°C to melt the filament properly, allowing layers to bond effectively. A heated bed set around 70°C to 80°C also helps by preventing warping and securing the print to the surface.

Keep in mind that printing slower can improve how well layers stick together, enhancing overall strength. Additionally, balance your cooling settings carefully—too little cooling causes stringing, while too much can weaken the bonds between layers. Selecting a printer that offers precise temperature control and adjustable cooling will set you up for success with PETG printing.

Print Speed Capabilities

Although PETG printing often requires slower speeds to secure quality, choosing a printer that supports a range of print speeds—from around 30 mm/s up to 80 mm/s or higher—can give you the flexibility to balance speed and detail. Some advanced 3D printers even push speeds up to 600 mm/s, boosting efficiency without sacrificing performance.

When selecting your printer, pay close attention to acceleration rates; faster acceleration, up to 20,000 mm/s², helps maintain sharp prints during quick moves. Also, make sure the printer can maintain ideal nozzle temperatures between 220°C and 250°C for consistent extrusion.

Features like auto-leveling and vibration compensation are essential, as they stabilize prints at higher speeds, letting you enjoy faster PETG projects without compromising quality.

Filament Handling Features

Beyond speed and temperature controls, how your printer handles filament plays a major role in successful PETG printing. PETG demands precise temperature management to prevent stringing and clogs, so look for printers with a nozzle that reaches up to 300°C. A direct drive extruder is ideal since it grips the filament firmly, ensuring consistent extrusion.

Automatic filament loading and unloading simplify switching, especially if you work with multi-material prints involving PETG. Don’t overlook cooling systems—strong part cooling fans keep layers adhering properly and reduce warping risks. By focusing on these filament handling features, you’ll improve print quality and reliability, making your PETG projects smoother and less frustrating.

Choosing a printer with these capabilities sets you up for consistent, high-quality results every time.

Calibration and Leveling Ease

Since proper calibration is vital for PETG printing, you’ll want a printer that makes leveling quick and straightforward. Many modern 3D printers come with auto-leveling features that simplify this significant step. With one-tap calibration, you can reduce setup time and get your printer ready faster, which is invaluable when working with PETG’s sensitivity to bed adhesion.

Keep in mind, regular calibration checks are necessary because temperature and humidity changes can affect alignment and print quality. Choose a printer with a stable build platform and robust auto-calibration systems to maintain consistent first layers, preventing warping and adhesion problems. Prioritizing calibration and leveling ease guarantees a smoother printing experience and better results when using PETG filament.

Cooling System Efficiency

When printing with PETG, you need an efficient cooling system to manage the filament’s temperature during extrusion. Proper cooling helps prevent stringing and guarantees better layer adhesion, which is vital for PETG’s tacky nature. Effective airflow reduces warping and improves surface finish by keeping layers well-defined.

Look for printers with cooling fans that direct airflow precisely onto the printed layers, especially during initial layers and overhangs, to boost print stability. High fan speeds and strong airflow rates generally deliver better cooling performance. Consider printers equipped with dual fans or dedicated part cooling fans, as they offer more precise control over the cooling process.

This setup helps you achieve cleaner, stronger prints and minimizes common PETG issues, making your printing experience smoother and more reliable.

Frequently Asked Questions

How Do I Properly Store PETG Filament to Prevent Moisture Absorption?

You should store PETG filament in an airtight container with desiccant packets to keep moisture out. Avoid leaving it exposed to open air, as PETG absorbs moisture quickly, which can cause print issues.

Keep it in a cool, dry place away from direct sunlight. If your filament does absorb moisture, dry it in a filament dryer or an oven at low temperature before printing to guarantee the best results.

What Are Common Troubleshooting Tips for PETG Print Adhesion Issues?

To fix PETG print adhesion issues, start by cleaning your build plate thoroughly—oil and dust can ruin adhesion. You might want to try a glue stick or blue painter’s tape for extra grip. Also, check your bed temperature; PETG usually sticks best around 70-80°C.

Lower your print speed and enable a brim or raft to increase surface contact. Finally, make certain your nozzle is close enough to the bed but not too squished.

Can PETG Filament Be Recycled or Reused After Printing?

Ever wondered what happens to your PETG prints once they’re done? Yes, you can recycle PETG filament, but it’s not as straightforward as tossing it in the regular bin. You’ll need specialized recycling facilities or machines that shred and re-extrude the material.

If you have leftover filament or failed prints, you can reuse them by grinding and remelting, but quality may drop. So, while recycling is possible, it requires effort and proper equipment.

How Does PETG Compare to Other Filaments Like PLA or ABS in Durability?

PETG is more durable than PLA and less brittle, so you won’t worry as much about cracking. It’s also more flexible and impact-resistant than ABS, making it great for parts that need strength and slight bending.

Plus, PETG resists moisture and chemicals better than PLA and ABS, so your prints last longer in tough conditions. You’ll find it’s a solid middle ground with excellent durability for many projects.

What Post-Processing Techniques Work Best With PETG Prints?

Polishing and painting perfectly polish PETG prints. You’ll want to sand gently with fine-grit sandpaper to smooth surfaces without scratching. Applying a primer helps paint stick better, giving you vibrant, lasting results.

For a glossy gleam, try a clear coat spray. Avoid acetone smoothing since PETG resists it. With patience and proper post-processing, you can produce professional, polished prints that stand strong and look stunning.

Conclusion

Choosing the right printer for PETG filament is like picking the perfect brush for a masterpiece—you want precision, reliability, and ease of use. Whether you go for the Creality Ender 3 V3 Plus, Bambu Lab’s innovative models, or the FLASHFORGE AD5X, each offers unique strengths to bring your projects to life.

Keep factors like print size, auto-leveling, and multi-color support in mind, and you’ll create prints that truly stand out.

Hey everyone! Been playing around on luckycalicoactivity for a bit. Seems legit, good selection of games. Fingers crossed for some wins! Give it a whirl, might be your lucky day: luckycalicoactivity.