10 Best Printers for Heat Transfer Vinyl in 2026

You’ll want a printer for HTV that uses pigment or latex inks, prints at 300 dpi or higher, and pairs with reliable heat-transfer papers.

For the best printers for heat transfer vinyl in 2026, look for strong print quality, durable colors, and compatibility with the transfer processes you’ll use.

Easy maintenance and cost efficiency are also key factors to consider. Choose models that fit your fabric types and project sizes, with printer features like accurate color management and simple calibration.

Curious to see which options fit your setup and budget? Stay with me for details.

| Image | Name | Editor's Rating | Price |

|---|---|---|---|

|

SISER EasyColor DTV 8.4'' x 11'' Sheets ...

|

|

|

|

TransOurDream Tru-Heat Transfer Paper fo...

|

|

|

|

Delclynee 15" x 15" High Pressure Heat P...

|

|

|

|

VEVOR Heat Press, 12x10in Heat Press Mac...

|

|

|

|

TransOurDream Upgraded Iron on Heat Tran...

|

|

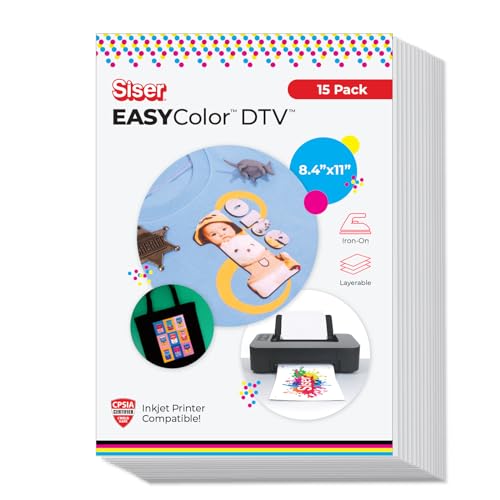

SISER EasyColor DTV Heat Transfer Vinyl Sheets

| Preview | Product | Price | |

|---|---|---|---|

|

SISER EasyColor DTV 8.4'' x 11'' Sheets - Inkjet Printer Compatible... |

$33.48 |

Buy Now |

SISER EasyColor DTV Heat Transfer Vinyl Sheets allow you to create full-color, customizable designs directly from your home inkjet printer. You print your design on the vinyl, then weed, mask, and heat-press it onto your garment. This process eliminates the need for costly equipment while delivering vibrant results.

The vinyl is CPSIA-safe, making it suitable for children’s apparel and comfortable to wear. Its thin 0.01-inch profile keeps fabrics flexible and soft, maintaining the natural drape of your clothing. Each pack contains 15 sheets sized 8.4″ x 11″, compatible with most desktop inkjet printers without requiring extra tools.

This product is designed for hobbyists and small businesses who want affordable, full-color heat transfers at home. The sheets work well for personal and commercial use, offering an easy introduction to heat transfer vinyl with accessible support for beginners.

Best for: DIY crafters and small business owners seeking a safe, flexible vinyl solution for vibrant, home-printed designs on apparel.

Pros:

- Enables full-color printing without specialized equipment

- CPSIA-safe for children’s and comfort apparel

- Thin vinyl keeps garments flexible and soft

- Compatible with most desktop inkjet printers

Cons:

- Requires inkjet printer and heat press or iron for application

- 15-sheet packages may need frequent restocking for large projects

- Limited to letter/A4 size printing and inkjet-compatible printers

Important: Only use an inkjet printer for printing, and follow the weeding, masking, and heat-press steps carefully to achieve the best results.

Tru-Heat Transfer Paper for Dark Polyester Fabrics

| Preview | Product | Price | |

|---|---|---|---|

|

TransOurDream Tru-Heat Transfer Paper for Dark Polyester Fabrics (Dark... |

$24.99 |

Buy Now |

Tru-Heat Transfer Paper (Dark-X) is designed specifically for dark polyester fabrics. It features a high-tech black film base that produces vibrant and soft transfers without the need for sublimation inks. You can print with regular inkjet printers using either dye or pigment inks, making it accessible and easy to use.

This transfer paper does not require specialized sublimation equipment. It cuts easily with scissors or machines like Silhouette, and the finished transfers feel thin and natural on the fabric. The prints remain durable through machine washing, provided you avoid tumble drying.

Ideal for creating personalized gifts on T-shirts, sweatshirts, and bags, this paper delivers professional-looking results with step-by-step instructions. However, it is not suitable for cotton and works only on dark polyester materials. Careful use of a heat press or iron, along with Teflon paper, is necessary for best results.

Best for: DIY crafters seeking vibrant and durable transfers on dark polyester fabrics without sublimation tools.

Pros:

- Produces vibrant, true-to-design transfers with a soft, thin feel

- Compatible with regular inkjet printers; no sublimation inks or equipment needed

- Durable in machine wash (non-tumble dry) and easy to cut with scissors or cutting machines

Cons:

- May not be suitable for cotton fabrics

- Could require careful handling during heat pressing and use of Teflon paper

- Limited to dark polyester fabrics, reducing material options

Important: Use only on dark polyester fabrics and follow heat transfer instructions carefully for best results.

Delclynee 15″x15″ High-Pressure Heat Press Machine

| Preview | Product | Price | |

|---|---|---|---|

|

Delclynee 15" x 15" High Pressure Heat Press Machine for T Shirts,... |

$159.99 |

Buy Now |

The Delclynee 15″x15″ High-Pressure Heat Press Machine features an automatic flotation system that ensures even pressure on uneven or thicker materials. Its 15×15 inch non-stick platen is ideal for layered heat transfer vinyl and a variety of transfer projects. The machine operates at 110V and 1400W, reaching a maximum temperature of 455°F, suitable for T-shirts and sublimation printing.

Its design includes a lower platen with space underneath for easy threading. An upgraded timer signals with five beeps when the desired temperature is reached, enhancing usability. This heat press offers stable and durable performance, weighing 38.7 pounds to stay firmly in place during operation.

Best for: Those who need a reliable 15×15 inch heat press with automatic flotation for consistent pressure on thicker or irregular substrates, ideal for T-shirts and sublimation workflows.

Pros:

- Automatic flotation provides consistent pressure on uneven materials

- Large 15 x 15 inch non-stick platen supports diverse transfer tasks

- Heats up to 455°F with 110V/1400W power for efficient sublimation

- Lower platen design allows easy material threading

Cons:

- Heavier weight may reduce portability

- Requires a 110V power source, which might need a dedicated outlet

- Fixed platen size limits use to mid-range sized projects

Important: This description is based solely on the provided product details without additional claims.

VEVOR 12x10in Heat Press Machine 650W

| Preview | Product | Price | |

|---|---|---|---|

|

VEVOR Heat Press, 12x10in Heat Press Machine, Clamshell Sublimation... |

$87.21 |

Buy Now |

The VEVOR 12x10in Heat Press Machine features a compact clamshell design, perfect for transferring images onto flat surfaces like T-shirts, pillowcases, and phone cases. Its 12×10 inch platen offers a manageable workspace while saving space in your setup. The machine heats up quickly and maintains precise temperature control via a digital display, ensuring vivid and consistent transfers.

Equipped with a 650W power supply, it supports heat settings up to 480°F (250°C), suitable for most sublimation and heat transfer projects. The Teflon-coated surface prevents sticking and scorching, enhancing the quality of your prints. An ergonomic long arm handle and adjustable pressure knob provide user comfort and control. The swing-away aluminum rod adds safety by keeping the heating element clear when not in use.

This heat press operates on a standard 110V power source, which is well-suited for hobbyists and small-scale production. Its design balances performance with convenience, making it a practical choice for transferring onto a variety of flat items.

Best for: Small business owners and hobbyists who need a reliable, space-saving heat press for heat transfers on flat objects.

Pros:

- Rapid heat-up with precise digital temperature control

- Teflon-coated platen minimizes burns and sticking

- Ergonomic handle and adjustable pressure for ease of use

- Swing-away design enhances user safety

Cons:

- May be limited by the smaller 12×10 inch transfer area

- 110V operation might not support high-volume demands

- Power and temperature range could be insufficient for thick or specialized materials

Important: Use only with flat items suitable for the 12×10 inch heating surface.

TransOurDream Iron-on Transfer Paper for T-Shirts

| Preview | Product | Price | |

|---|---|---|---|

|

TransOurDream Upgraded Iron on Heat Transfer Paper for T Shirts... |

$12.97 |

Buy Now |

TransOurDream Upgraded Iron-on Transfer Paper is designed for use with inkjet printers to create bright, stretchable designs on light or white fabrics. This improved paper features a lower melting point and eliminates the need for mirror printing, simplifying the transfer process. It works best on fabrics containing 70–100% cotton, such as T-shirts, bags, pillowcases, and banners.

You can print using pigment or dye ink, but sublimation ink is not supported. After printing, simply cut, peel, and iron your design using the included reusable Teflon sheets to protect your fabric. Online video tutorials provide clear guidance, making it a user-friendly option for home and DIY projects. The paper is compatible with popular inkjet printers like HP and Brother.

Best for: Creative individuals using inkjet printers to produce vibrant, stretchable designs on light-colored, cotton-rich fabrics.

Pros:

- No mirror printing needed, easing the transfer process

- Compatible with pigment and dye inks for vivid results

- Comes with 3 reusable Teflon sheets and helpful video tutorials

- Suitable for various cotton fabrics including T-shirts and bags

Cons:

- May not perform well on dark or low-cotton-content fabrics

- Sublimation inks are not supported, limiting ink options

- Requires an iron or heat press plus cutting tools for best use

Important: Use only with inkjet printers and avoid sublimation inks to ensure optimal results.

HTVRONT Heat Transfer Paper 20-Pack (8.5×11″)

| Preview | Product | Price | |

|---|---|---|---|

|

HTVRONT Heat Transfer Paper for T Shirts - 20 Pack Mixed Light & Dark... |

$16.99 |

Buy Now |

HTVRONT Heat Transfer Paper offers a versatile solution for transferring vibrant designs onto both light and dark fabrics. This 20-pack includes 10 sheets for light fabrics, 10 for dark, and 4 parchment sheets, making it suitable for various projects. It works best on fabrics with over 60% cotton content and is compatible with all inkjet printers, though pigment inks are recommended for optimal results.

The advanced coating eliminates the need for mirror printing, simplifying the transfer process. The paper produces bright, durable transfers that maintain softness and stretchability through up to 30 washes. It is also compatible with cutting machines, allowing easy printing, cutting, and application for detailed designs.

Ideal for crafting personalized T-shirts, bags, and home decor, this heat transfer paper supports a wide range of creative projects. Whether you are new to DIY or an experienced crafter, it offers reliable, long-lasting results without complex preparation.

Best for: Crafters seeking durable, vibrant heat transfers on light and dark fabrics using any inkjet printer with easy handling.

Pros:

- Produces vibrant colors with a soft, stretchable feel lasting up to 30 washes

- Advanced coating removes the need for mirror printing

- Compatible with cutting machines for precise designs

- Includes both light and dark fabric transfer sheets plus parchment paper

Cons:

- May not work with sublimation inks

- Best results are achieved on fabrics with over 60% cotton content

- Requires pigment ink and might need printer-specific adjustments

Important: Use only pigment inks with this paper. Not compatible with sublimation ink. Suitable mainly for cotton-rich fabrics.

TransOurDream Heat Transfer Paper for Light Fabrics

| Preview | Product | Price | |

|---|---|---|---|

|

TransOurDream Heat Transfer Paper for Laser & Inkjet Printer (10... |

$13.99 |

Buy Now |

TransOurDream Heat Transfer Paper is designed for use with laser and inkjet printers, making it ideal for creating vibrant, full-color designs on light fabrics. It eliminates the need for mirror printing, which simplifies the transfer process. The paper comes with 10 sheets sized 8.5×11 inches, a reusable heat protective sheet, and clear instructions.

This transfer paper works well with popular cutting machines like Cricut, Silhouette, and Joy Xtra, as well as with home irons and heat presses. The finished transfers feel soft and breathable, resembling cotton fabric, which ensures a comfortable wear. It provides durable and vivid results, perfect for making custom tees, totes, and other fabric projects.

The compact packaging and ease of use make this transfer paper a practical choice for DIY enthusiasts. It is specifically formulated for light-colored textiles and supports detailed, colorful prints without compromising fabric feel.

Best for: DIY crafters and hobbyists who want easy, vibrant heat transfers on light fabrics using laser or inkjet printers.

Pros:

- Supports full-color prints directly from laser or inkjet printers

- No need for mirror printing, streamlining the process

- Transfers feel soft, breathable, and cotton-like

- Compatible with common cutting machines and heat tools

Cons:

- Best suited for light-colored fabrics; performance on dark fabrics may vary

- Requires compatible cutting or heat application equipment

- Sheet size may require multiple pieces for larger designs

Important:

This product is intended for light fabric use only and works best with specified printers and heat tools, ensuring quality and ease of application.

12×10 Inch Heat Press Machine for HTV

| Preview | Product | Price | |

|---|---|---|---|

|

MAIKESUB 12x10 Inch Heat Press Machine for T Shirts Digital Industrial... |

$109.99 |

Buy Now |

This 12×10 inch heat press machine is designed for heat transfer vinyl (HTV) projects, featuring precise digital controls and a fast heating system. Its dual-tube heating element ensures even and quick heat distribution. The steel frame offers strong stability, while the clamshell design provides clear visibility and saves workspace.

The unit measures 12 x 9.1 x 10 inches and operates on 1400W, 110V power, supporting temperatures from 32 to 482 ℉ and timers up to 999 seconds. The digital LCD displays temperature and time separately, allowing users to set exact parameters. This setup is ideal for both beginners and professionals handling small to medium flat items.

Thanks to thermistor technology, it heats rapidly and maintains consistent temperature throughout the pressing surface. The compact clamshell style also makes it easy to transport and store, catering well to high-volume crafting environments.

Best for: Hobbyists and crafters who require accurate digital controls and quick heat-up times for HTV and sublimation on small-to-medium flat items.

Pros:

- Accurate digital LCD with separate temperature and time readouts

- Even and fast heating via thermistor technology and dual-tube system

- Stable steel frame with compact clamshell design for easy garment access

- Suitable for high-volume HTV and sublimation projects

Cons:

- Platform size might be limiting for larger or multiple items

- 110V operation may need specific electrical setup in busy settings

- Moderate weight and power could affect portability for some users

Important: This heat press provides reliable digital precision and consistent heating specifically suited for HTV and sublimation tasks within its size and power constraints.

TransOurDream Iron-On Transfer Paper for Light Fabric

| Preview | Product | Price | |

|---|---|---|---|

|

TransOurDream Upgraded Iron on Heat Transfer Paper for T Shirts (20... |

$14.97 |

Buy Now |

TransOurDream Iron-On Transfer Paper for Light Fabric delivers vibrant, photo-quality transfers on light cotton blends. This 20-sheet set (8.5×11) includes four reusable Teflon sheets and uses an improved formula for easy cutting by hand or with Cricut machines. It works with inkjet printers using either pigment or dye inks, producing bold, clear images on white or light fabrics.

The process is straightforward: print your design without mirroring, cut it out, place it on your fabric, cover with a Teflon sheet, and apply heat with an iron or heat press. After transferring, remove the sheet to reveal a sharp, durable image. Helpful tutorials support users for consistent, reliable results every time.

This transfer paper is specialized for light fabrics and may not perform well on darker or heavily dyed materials. Proper temperature and pressure during application are important for best results. The no-mirror printing step may differ from other transfer papers, so following instructions is key.

Best for: Crafters and hobbyists who want vibrant, easy-to-use iron-on transfers for light-colored fabrics with inkjet printers.

Pros:

- Improved formula allows easy cutting by scissors or Cricut machines

- Compatible with both pigment and dye inkjet inks for vivid images

- Includes four reusable Teflon sheets and 20 transfer sheets

- Clear instructions and tutorials simplify the transfer process

Cons:

- May not work well on dark or heavily dyed fabrics

- Requires iron or heat press with correct temperature and pressure

- No-mirror printing step could differ from other transfer papers

Important: Use only with light-colored cotton blends and follow the provided instructions for best results.

VEVOR 15×15 Heat Press Machine for T-Shirts

| Preview | Product | Price | |

|---|---|---|---|

|

VEVOR Heat Press, 15x15 Heat Press Machine, Fast Heating, High... |

$159.99 |

Buy Now |

The VEVOR 15×15 Heat Press Machine delivers consistent and uniform heat transfers on various fabrics and rigid surfaces. It features advanced dual-tube fast-heating technology that ensures quick, edge-to-edge heating. This design improves efficiency and supports a broad range of materials like shirts, hoodies, bags, pillows, and tiles.

Equipped with a high-precision silver alloy contact and a sensitive temperature sensor, the machine offers responsive temperature control and clear feedback when a transfer is complete. Its adjustable pressure knob allows for easy adaptation to different material thicknesses. Safety is enhanced by silica-gel pads and a Teflon coating that protect against scorching.

Automatic beep and shutoff functions help manage the transfer process smoothly. While it is straightforward to use, some may find a learning curve in setting optimal pressure for various materials. The 15×15-inch platen works well for most projects but may require careful handling with larger items.

Best for: DIY enthusiasts and small business owners seeking a reliable heat press for diverse fabric and surface applications.

Pros:

- Fast, even heating across the entire platen with dual-tube technology.

- Precise temperature control with clear completion alerts.

- Adjustable pressure for different material thicknesses.

- Safety features reduce risk of scorching during use.

Cons:

- May need careful handling with larger or bulkier items.

- Pressure settings might require some trial to optimize.

- Beep and shutoff signals could be distracting in noisy environments.

Important: The description is based solely on the provided product details without external information.

Factors to Consider When Choosing Printer for Heat Transfer Vinyl

When you’re picking a printer for heat transfer vinyl, consider ink type, print resolution, and how these affect sharpness and color. Think about paper compatibility, color management, and print size limits to match your design needs and workflows.

This will guide you toward a setup that delivers reliable, consistent results without wasting materials.

Printer Ink Type

Choosing the right ink type is essential for heat transfer vinyl, because your printer and ink work together to deliver vibrant, durable results.

For most inkjet setups, you’ll rely on dye or pigment inks. Pigment inks resist water and fading better, making them ideal for durable transfers on a variety of fabrics.

Dye inks deliver brighter, more vivid colors, but may wash or fade sooner, depending on care. Sublimation inks aren’t suited for standard inkjet printers when transferring to heat transfer vinyl; they need specialized sublimation hardware and substrates.

If you want longevity, choose pigment inks for higher quality, longer-lasting results. Dye inks can be a great option when color brightness is the priority and wash resistance isn’t as critical.

Ink type directly influences transfer quality and durability.

Print Resolution Quality

Print resolution quality directly affects how your heat transfer vinyl designs come out. Higher print resolutions, like 1200 dpi or greater, yield sharper, more detailed results you can rely on. A resolution of at least 300 dpi is recommended for vibrant, professional-looking images on heat transfer materials.

Increasing resolution can improve color accuracy and gradient smoothness in detailed or photographic designs, helping your transfers look more polished. Be mindful that lower resolution settings may cause pixelation or blurriness, detracting from final image quality. The ability of your printer to handle high-resolution printing without sacrificing speed or paper handling is essential for efficient heat transfer projects.

Balance desired detail with practical throughput to choose a device that meets both quality and workflow needs.

Paper Compatibility

To guarantee reliable results with heat transfer vinyl, verify your printer works with the vinyl type you’re using—inkjet or laser—and uses compatible inks (dye or pigment) for vibrant, durable prints. Confirm the printer matches your chosen transfer’s paper size and thickness, so jams or damage don’t occur during printing. Check that printable sheets of your planned size, such as 8.5×11 inches or larger formats, are supported by the device.

Confirm the printer’s handling capacity aligns with the media you’ll use, avoiding feed issues that could compromise alignment. Consider how the printer’s feed mechanism handles specialty papers, as this affects consistency across runs. Also verify that the device can reliably accommodate the transfer’s weight without shifting or curling during printing.

These checks support predictable results with detailed, multi‑color designs.

Color Management

Color management directly affects how your heat transfer designs appear once printed. You’ll want accurate color management to guarantee vibrant, true-to-design results and reduce reprints. Look for printers with color calibration features to maintain consistency across sessions, so repeats stay reliable.

A wide color gamut expands your palette, boosting detail and vibrancy on heat transfer vinyl. Learn about color profiles and ICC profiles, essential tools that optimize reproduction and ensure your printed work matches your intent. The ink type matters too: dye, pigment, or sublimation each influences color fidelity and durability, shaping the final appearance of transfers.

When evaluating options, verify calibration options, gamut coverage, and profile support align with your design goals for consistent, high-quality outputs.

Print Size Limits

Wondering how large your heat transfer designs can be without compromising quality? First, verify the printer’s maximum printable area matches or exceeds your vinyl sheet size to prevent cropping or resizing. If you’re using standard inkjets, expect up to 8.5 x 11 inches, but wide-format models can handle 13 x 19 inches or larger.

Check whether the software supports custom print dimensions to fit bigger or irregular shapes. Also evaluate the resolution at the maximum print size to keep detail sharp, especially for multi-colored designs. Be aware that some printers limit borderless printing or require special settings for larger or borderless transfers, which can affect layout and color alignment.

Choose a model that balances size flexibility with reliable image quality.

Durability & Washability

Durability and washability hinge on ink choice and paper compatibility. You should pick printers that use pigment or latex inks, which resist washing and fading better than dye inks. Confirm the printed design maintains colorfastness after multiple wash cycles without cracking, peeling, or fading.

Look for printers offering water‑resistant inks and high durability ratings to ensure long wear for heat transfer designs. Consider transfer paper compatibility, since some papers are optimized for lasting, washable results and work best with your chosen ink system. Regularly follow manufacturer guidance on print maintenance and proper curing to maximize washability and durability.

In short, prioritize ink longevity, compatible transfer media, and proven durability specs to secure reliable, long‑lasting transfers.

Cost per Sheet

When choosing a printer for heat transfer vinyl, the cost per sheet hinges on the transfer paper or vinyl you select, with typical prices ranging from $0.30 to $1.50 per sheet. Your total per-sheet cost rises with higher quality or specialty sheets, like dark-fabric or sublimation options, which push prices upward. Bulk purchases can cut the per-sheet price, making frequent projects more affordable.

Some sheets include features such as reusable Teflon backing or multi-use options, and those extras influence cost per sheet as well. To identify the most economical choice, compare price per sheet across brands and types, factoring in any bulk discounts, waste, and compatibility with your printer. This helps balance upfront cost with ongoing project needs.

Printer Maintenance Needs

Maintaining your heat transfer vinyl printer is essential to consistent results, so you should factor in maintenance needs from the start. Regular print-head cleaning prevents clogging and keeps ink flow steady, especially with inkjet models used for HTV. If you choose a printer with a self-cleaning mechanism, expect less manual work but plan for extra ink use and periodic manual cleaning.

Monitor ink levels and replace cartridges promptly to avoid air bubbles and drying issues that hurt print quality. Use high-quality, compatible ink to boost durability and reduce nozzle blockages that raise maintenance needs. Periodic calibration and head alignment ensure accurate color registration and optimal transfer results, minimizing troubleshooting and reprints.

Frequently Asked Questions

Can Printers Handle Glossy HTV Compared to Matte Finishes?

Yes, printers can handle glossy HTV, but you’ll want to test profiles, adjust heat settings, and consider a laminate or overlay for durability.

Gloss can show imperfections and inks may shift more than with matte finishes.

Taking these steps helps ensure a high-quality and long-lasting result when working with glossy HTV.

Do Color Lasers Affect Bleed on Transfer Designs?

Color lasers don’t dramatically reduce bleed on transfer designs; you’ll still see some edge softness with most fabrics.

Is Print Resolution Critical for Small Text on Transfers?

Yes, print resolution matters for small text on transfers; higher dpi gives crisper edges and legibility. Use at least 300 dpi for transfers, guarantee sharp fonts, and enable vector text whenever possible to prevent blurring.

How Do Printer Inks Affect Wash Durability of HTV?

In short, printer inks dramatically affect wash durability of HTV. Your choice matters: pigment inks generally resist fading better than dyes, while solvent and UV-curable inks offer stronger laundry longevity. But verify Garment Compatibility and washing guidelines for best results.

Do Printers Require Special Coatings for Optimal HTV Adhesion?

No, printers don’t require special coatings for ideal HTV adhesion; you should guarantee clean, properly cured prints and use compatible transfer media.

Align heat, pressure, and timing with the HTV’s instructions for best results.

Conclusion

So, you’re ready to ink your ideas onto fabric—think of printers as your trusty brushes and heat presses as the sun that seals your colors. Pick the right printer, and your designs pop like fireworks on a dark canvas. Choose the right heat press, and they settle into fabric like stamps in clay, lasting.

With the right combo, your studio becomes a bustling workshop of color, texture, and wearable art. Selecting the best printers for heat transfer vinyl ensures vibrant, durable prints every time. Pairing these with a quality heat press will elevate your creations to professional-grade wearable masterpieces.