10 Best Vinyl Heat Press 15×20 Clamshells for 2026

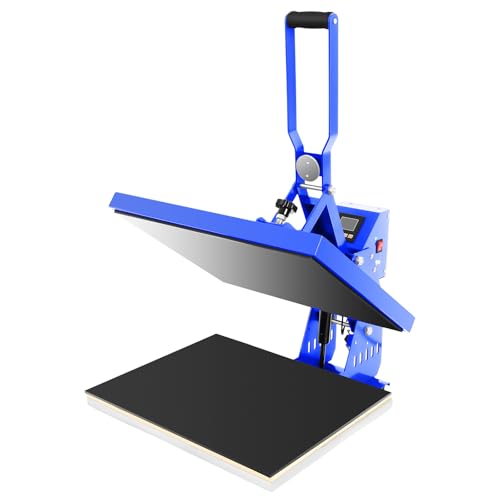

You’ll want a 15×20 clamshell heat press that’s built for steady transfers and easy handling. Look for models with 1600–1800W, accurate digital controls, auto-open safety, and durable non-stick platens for even heat.

These presses suit vinyl, sublimation, and large-format jobs, making them ideal for various crafting needs.

These machines feature sturdy frames, fast heat-up times, and reliable pressure to ensure consistent results.

Consider workspace size, 110V compatibility, and a solid platen finish to prevent scorching during transfers.

Finding the right balance between power and usability is key for your projects.

Want more specifics and top picks tailored to 2026 choices? You’ll find them as you continue exploring the best vinyl heat press 15×20 clamshells available this year.

| Image | Name | Editor's Rating | Price |

|---|---|---|---|

|

VEVOR 16x20 Heat Press, 1700W High Press...

|

|

|

|

Sanshare Heat Press Covers 15x15/16x20/1...

|

|

|

|

SmarketBuy Heat Press Machine 16x20 Inch...

|

|

|

|

Usoraszkt 16 “x 20” inch Clamshell a...

|

|

|

|

HTVRONT Heat Press Mat - Heat Press Pad ...

|

|

VEVOR 16×20 Heat Press with Digital Control

| Preview | Product | Price | |

|---|---|---|---|

|

VEVOR 16x20 Heat Press, 1700W High Pressure Clamshell Heat Press... |

$266.90 |

Buy Now |

The VEVOR 16×20 Heat Press with Digital Control features a powerful 1700W dual-tube heating system that heats up quickly to 570°F (299°C). It offers precise temperature control and consistent heat distribution across its large 16×20 inch non-stick platen. The clamshell design allows for easy access, while the adjustable pressure knob ensures even transfers on various material thicknesses.

This heat press includes electronic controls for time and temperature, making it simple to set accurate parameters for each project. A silicon pad beneath the platen helps with easy maintenance and protects materials during pressing. The machine automatically stops heating once the set temperature is reached, providing reliable and repeatable results every time.

Best for: hobbyists and small to mid-sized businesses needing a high-power heat press for vinyl, sublimation, and heat transfer projects with large-format designs and precise temperature management.

Pros:

- Rapid heating with 1700W dual-tube system up to 570°F (299°C)

- Large 16×20 inch non-stick platen for bigger designs

- Digital time and temperature controls for accuracy

- Adjustable pressure knob for various material thicknesses

Cons:

- Clamshell design might be less ideal for very thick substrates or frequent handling

- Heavier unit may need more workspace and occasional setup time

- Non-stick coating and silicon pad replacements could lead to maintenance costs

Important: This description is based solely on the provided product details without external information.

Sanshare Heat Press Covers 16×20 2-Piece Set

| Preview | Product | Price | |

|---|---|---|---|

|

Sanshare Heat Press Covers 15x15/16x20/16x24 for Top and Bottom... |

$19.59 |

Buy Now |

The Sanshare Heat Press Covers 16×20 2-Piece Set offers dependable protection for both platens of your heat press. Each cover features a dual-Teflon construction that safeguards surfaces from ink and adhesive stains. The covers are designed specifically for the 16×20 platen size, making installation straightforward.

Crafted with high-density knitted Teflon, the covers deliver excellent heat resistance and durability. Their heat-resistant silicone surface is easy to clean and resists residue buildup. This non-stick feature helps maintain performance and keeps daily maintenance hassle-free.

This two-piece set includes one cover for the top platen and one for the bottom platen, providing comprehensive platen protection. It is especially useful for users who require consistent, long-lasting coverage during frequent heat press operations.

Best for: Users who regularly operate a 16×20 heat press and need reliable protection for both platens with minimal upkeep.

Pros:

- Dual-Teflon construction protects both top and bottom platens effectively

- Durable and resistant to high temperatures for frequent use

- Non-stick silicone surface wipes clean easily and resists residue

Cons:

- May require managing two separate covers during installation

- Could serve as a temporary solution if used heavily beyond material limits

Important:

This product is specifically designed for 16×20 heat press platens and focuses on protecting against ink and adhesive while offering heat resistance and easy cleaning.

SmarketBuy 16×20 Heat Press Machine with Digital Control

| Preview | Product | Price | |

|---|---|---|---|

|

SmarketBuy Heat Press Machine 16x20 Inch, High Pressure Clamshell Heat... | $254.90 | Buy Now |

The SmarketBuy 16×20 Heat Press Machine features a large 16×20 inch heating surface that accommodates a variety of transfer projects. It offers fully digital temperature and timer controls, allowing precise adjustments from 0 to 400°F and up to 999 seconds. This makes it suitable for consistent transfers on T-shirts, bags, and plates.

Its design includes a Teflon-coated plate for even heat distribution and a thickened surface that maintains stable temperatures. The soft liner helps reduce odors during use. An upgraded hydraulic rod simplifies pressure settings, complemented by non-slip grips for better handling. The machine operates at 1700W on 110V, ensuring rapid heating and efficient performance.

Best for: Small businesses and enthusiasts requiring reliable, large-format heat transfer capabilities for apparel and accessories.

Pros:

- Large heating surface ideal for diverse projects

- Precise, fully digital temperature and timer control

- Rapid heating with 1700W power and easy pressure adjustment

- Non-slip grips enhance user control

Cons:

- Could require a sturdy workspace due to its weight

- Maximum temperature may limit some specialized uses

- Might be more than needed for casual or occasional hobbyists

16×20 Clamshell Auto Open Heat Press

| Preview | Product | Price | |

|---|---|---|---|

|

16 “x 20” inch Clamshell auto Open Heat Press Flip top Slide Out... | $276.99 | Buy Now |

The 16×20 clamshell auto-open heat press features a flip-top, slide-out base that makes loading designs safer and faster. It runs on 1800W power with high-efficiency aluminum heating plates and U-shaped tubes for even heat distribution. This ensures consistent results for high-volume transfer work.

The machine offers adjustable pressure through a simple knob and has a reinforced base with four rubber feet for added stability. Its smooth and quiet operation is supported by triple buffering rails and flat bearings, which ease lifting and pressing motions. The glossy, spray-molded finish adds durability and a professional look.

This heat press is designed for professionals and DIY crafters who need reliable, efficient equipment for frequent use. Its auto-open feature helps prevent overheating and simplifies handling during busy projects.

Best for: Professionals and hobbyists needing a 16×20 clamshell heat press with auto-open convenience for fast, safe, and consistent transfers.

Pros:

- Auto-open clamshell with flip-top, slide-out base for safer loading

- 1800W aluminum heating plates with U-shaped tubes for even heat

- Reinforced base and anti-slip feet provide stable operation

- Smooth, quiet lifting with triple-buffered rails and flat bearings

Cons:

- Workspace requirements may be considerable

- Availability and pricing might vary by retailer

- Price tracking requires sign-in, adding steps to research

Important: Information is based solely on provided data without external additions.

HTVRONT 16×20 Heat Press Mat for Vinyl Transfers

| Preview | Product | Price | |

|---|---|---|---|

|

HTVRONT Heat Press Mat - Heat Press Pad 16"x20" for Craft Vinyl... |

$21.99 |

Buy Now |

The HTVRONT 16×20 Heat Press Mat is designed to provide a stable and even surface for heat transfer projects. Its 7-layer composite construction ensures consistent heat distribution and moisture resistance, which helps achieve clean and professional results on vinyl, sublimation, and other heat-applied materials. The mat measures 16×20 inches and withstands temperatures up to 428°F (220°C), making it suitable for a wide range of heat press machines.

This heat press mat offers a flat, stable working area that eliminates guesswork about orientation during use. It is both lightweight and durable, weighing just 250 grams, and protects your work surfaces from heat damage. Compatible with Cricut machines and many other heat press devices, it is reusable and flame-retardant, contributing to a reliable crafting experience.

Best for: Makers and crafters who need a versatile, large heat press mat that provides even heat distribution and surface protection for vinyl transfers and sublimation.

Pros:

- 7-layer composite design for even heat and moisture resistance

- Large size fits most 16×20 heat press setups and Cricut-compatible devices

- Reusable, durable, and flame-retardant up to 428°F (220°C)

Cons:

- May add slight weight to your setup despite being lightweight

- Could require flat storage to avoid creases, although packaging helps

- Some users might be cautious with the dual-sided design when handling heat tools

Important: Description is based solely on provided product details without added claims.

Heat Press Machine 16×20 Inch with Auto Open

| Preview | Product | Price | |

|---|---|---|---|

|

Heat Press Machine 16x20 Inch, Auto Open Clamshell Vinyl Heat Press... | $356.99 | Buy Now |

This 16×20 inch heat press machine with an auto-open feature offers precise and consistent heat transfer for a variety of materials. Its aluminum heating plate ensures even heat distribution across the surface. The digital controls allow easy adjustment of temperature and time, ranging from 0 to 400°F and up to 999 seconds.

The semi-automatic design enhances safety by opening automatically when the cycle completes, reducing the risk of burns. Its sturdy iron and aluminum construction provides durability, while the stable pressure adjustment accommodates different thicknesses. Anti-slip pads keep the machine secure during use.

With 1600W power at 110V, this heat press delivers reliable performance for projects like apparel, hats, bags, tiles, and gifts. The ergonomic handle and audible completion signal add convenience to every pressing task.

Best for: small businesses and DIY crafters seeking a dependable, semi-automatic heat press with hands-free auto-open for consistent sublimation on various substrates.

Pros:

- Even heat distribution from the 16×20 inch aluminum plate

- Auto-open function improves safety and ease of use

- Durable iron and aluminum construction with anti-slip pads

Cons:

- 1600W at 110V may require a dedicated power outlet

- Weight might affect portability and setup flexibility

- Maximum temperature of 400°F may limit use with some high-heat substrates

Important: This product description is based solely on the provided specifications without added external information.

Automatic Open 16×20 Heat Press with Digital Control

| Preview | Product | Price | |

|---|---|---|---|

|

16 inch x 20 inch Heat Press, Automatic Open Heat Press, Clamshell... | $289.99 | Buy Now |

The Automatic Open 16×20 Heat Press with Digital Control offers a user-friendly design for both beginners and professionals. Its clamshell style features a 16×20 inch platen, providing ample space for transfers on T-shirts, pillows, and sublimation materials. The automatic lid release enhances safety and convenience by opening the press once the cycle ends.

Equipped with a digital temperature controller and timer, this heat press ensures precise and consistent results throughout your projects. It operates on 110V with 1600W power, delivering steady heat across the aluminum plate. The adjustable pressure knob allows customization of compression for different materials, while the automatic opening prevents overheating and damage.

This heat press is ideal for those who require reliable, efficient heat transfer equipment with advanced electronic controls. Its sturdy build supports a smooth workflow, especially for larger designs that demand consistent pressure and temperature.

Best for: Users seeking a safe, automatic open heat press with digital controls for accurate transfers on various fabric and sublimation items.

Pros:

- Automatic lid release for improved safety and ease.

- Digital temperature and timer controls for precise results.

- Large 16×20 clamshell platen supports bigger designs.

- Adjustable pressure knob for tailored compression.

Cons:

- 110V operation may limit use to compatible outlets.

- 1600W power needs sufficient electrical capacity.

- Clamshell format might require more workspace.

Important: This product description is based solely on provided specifications and features.

Heat Press Nation 16×20 Auto-Open Heat Press

| Preview | Product | Price | |

|---|---|---|---|

|

Heat Press Nation Signature Series 16" x 20" Slide Out Drawer Heat... | $959.95 | Buy Now |

The Heat Press Nation 16×20 Auto-Open is designed for efficient and precise heat transfers. It features a drawer-style lower platen that slides out smoothly for easy access and accurate placement. The gas shock system allows the press to open automatically, reducing hand strain during long sessions.

This heat press offers a temperature range up to 400°F, suitable for various heat transfer applications. The SurePressure system ensures consistent pressure, enhancing the quality of each transfer. The unit’s controls include upgraded time and temperature gauges, making adjustments straightforward.

Weighing 116 pounds, the press is sturdy and stable during use. Its size and features make it a solid choice for both professionals and serious hobbyists who require reliable, hands-free operation and safe handling. The auto-open feature also adds a layer of safety by preventing overheating.

Best for: Professionals and hobbyists needing a hands-free, accurate 16” x 20” heat press for long, detailed transfer projects.

Pros:

- Auto-open with SurePressure ensures consistent pressure and safety

- Drawer-style lower platen improves accessibility and precision

- Upper temperature supports a wide range of heat transfer projects

- Gas shock opening reduces operator fatigue

Cons:

- Setup might require two people due to its weight

- Maximum temperature may limit highly specialized applications

- May need a sturdy workspace for optimal use

HTVFast 16×20 Digital Heat Press (Blue)

| Preview | Product | Price | |

|---|---|---|---|

|

HTVFast Digital 16" x 20" High Pressure Heat Press Blue – Commercial... | $479.99 | Buy Now |

The HTVFast 16×20 Digital Heat Press (Blue) offers a floating upper platen with center pressure adjustment. This design ensures even, edge-to-edge pressure for consistent results on large heat transfers. It features precise digital controls for time and temperature, combined with a non-stick platen to prevent scorching.

This commercial-grade heat press is built for frequent use, handling T-shirts, vinyl, and sublimation projects with ease. Its sturdy construction supports high-pressure performance, enhancing both reliability and safety during operation. The 16×20 inch bed size accommodates sizable designs without compromising accuracy.

With its robust design and user-friendly controls, this heat press is ideal for those needing dependable, consistent results. Best for: hobbyists and small to mid-sized businesses focused on frequent HTV and sublimation work requiring uniform pressure on large transfers.

Pros:

- Floating upper platen with center pressure adjustment for uniform pressure

- Digital time and temperature controls with a non-stick surface

- Commercial-grade build emphasizing durability and safety

- Suitable for various materials including vinyl and sublimation

Cons:

- May require ample workspace due to its footprint

- Warranty period might feel limited for very heavy use

- Availability may need monitoring for best purchasing options

Important: This description is based solely on provided specifications and features without external information.

CREWORKS 16×20 Inch Heat Press Machine

| Preview | Product | Price | |

|---|---|---|---|

|

CREWORKS 16x20 Inch Heat Press Machine with Slide Out Base, Auto Open... | $649.99 | Buy Now |

The CREWORKS 16×20 Inch Heat Press Machine features a slide-out base and auto-open clamshell design for easy, precise transfers. Its built-in handle and smooth rail sliding improve grip and reduce burn risk. The silicone and foam pads on the base ensure consistent results across fabrics, pillows, masks, and bags.

This heat press uses an electromagnetic system to automatically open the upper platen after the countdown. The digital control box allows temperature settings up to 480°F and a timer of up to 999 seconds for accurate heat application. Its sturdy construction includes an emergency stop for added safety.

Designed for versatility and reliability, this machine suits users who handle multiple projects or require precise textile transfers. Its easy operation makes it a practical choice for small businesses and hobby crafters.

Best for: Small businesses and hobbyists needing precise, automatic heat press transfers on various materials.

Pros:

- Auto-open clamshell and slide-out base simplify workflow and reduce burn risk

- Precise digital controls up to 480°F and 999 seconds for diverse applications

- Built-in handle and safety features like emergency stop enhance user safety

- Silicone and foam pads ensure quality transfers on multiple surfaces

Cons:

- The platen size might be larger than needed for very small projects

- Clamshell design could take up more space in tight work areas

- Requires electrical power and may need some practice for new users

Factors to Consider When Choosing Vinyl Heat Press 15X20 Clamshell

When you’re choosing a Vinyl Heat Press 15×20, start by checking platen size compatibility to guarantee it fits your projects. Look at the temperature range and pressure adjustment to handle different materials, then consider build durability and whether an auto-open feature is worth it for your workflow.

These factors shape reliability, ease of use, and long-term value.

Platen Size Compatibility

A 15×20 inch platen should be large enough to accommodate your projects while still fitting the clamshell design. Make certain the heat press platen size matches or exceeds 15×20 inches to handle your vinyl projects without cropping edges. Verify the clamshell design allows the platen to fully open and close without obstruction for easy placement and removal of items.

Check if the platen dimensions align with the largest items you plan to press, such as large banners or multiple garments, to prevent surprises. Consider whether the platen’s shape and surface area provide even heat distribution across the entire 15×20 inch surface for consistent transfers. Confirm that the platen size suits your intended applications, including T-shirts, bags, or larger fabric pieces, to maximize usability.

Temperature Range Limits

Temperature control matters more than you might think. You want a heat press that reaches at least 350°F for most vinyl and heat transfer jobs, ensuring you can handle standard and specialty materials. Check whether the maximum temperature limit covers higher-heat needs from certain sublimation or specialty vinyl types.

Your control system should provide precise adjustments so you can set and hold the exact temp within the required range. A wider temperature range adds versatility, letting you tackle different materials and transfer techniques without swapping machines. Also verify an automatic shut-off or safety feature at the upper limit to prevent overheating and damage.

With solid range control, you gain reliability and flexibility for diverse projects.

Pressure Adjustment Range

Pressure is king here: you want a range that fits a variety of vinyl types and substrate thicknesses, from thin heat transfer vinyl to thicker materials. The pressure adjustment range determines the minimum and maximum pressure you can apply, letting you match each project’s needs. A wider range gives you flexibility to handle different vinyls and substrates without swapping machines.

Precise control within the range guarantees consistent pressure, delivering high-quality, durable transfers. Some presses feature a full-range knob, so you can fine-tune for specific projects rather than guessing. Proper pressure range helps prevent under- or over-pressing, which can cause poor adhesion or vinyl damage.

Choose a model with clear indicators and reliable calibration to maintain repeatable results project after project.

Build Durability Matter

Durable construction matters because a heat press that holds up under frequent use delivers consistent results and fewer hassles. A sturdy build lets you operate day after day without warping or breaking, preserving steady performance over time. High-quality materials, like heavy-duty steel or reinforced aluminum frames, directly boost longevity and reliability.

Robust construction also minimizes vibrations and movement during pressing, which supports even heat transfer and precise results. With reinforced hinges and sturdy handles, you reduce the risk of mechanical failure, enabling safer, more dependable use. Investing in durability pays off, especially in high-volume environments, by lowering repair or replacement needs and overall operating costs.

In short, choose a model whose chassis and joints are engineered for long-term, demanding use.

Auto-Open Benefit

Auto-open heat presses release the platen automatically when time’s up, preventing over-pressing and scorching your project. You’ll notice the shift in workflow as soon as the timer ends, since you don’t have to yank garments or risk dragging the material. This feature enhances safety by reducing chances of burns or injuries during operation, making setup smoother for new users.

The hands-free release also means you can move on to the next item quickly, boosting overall efficiency without compromising quality. Because the material stays steadier after pressing, transfer consistency improves, minimizing misalignment from post-press shifts. If you’re learning heat pressing, auto-open delivers a forgiving, predictable process that helps you build confidence and repeatable results.

Heat Transfer Surface

A good heat transfer surface for a 15×20 clamshell should be at least 15×20 inches, non-stick or Teflon-coated for easy release and cleaning, and designed to distribute heat evenly across the entire area. You want a surface that is heat-resistant and durable, able to withstand repeated high temperatures without warping. A smooth, flat surface matters, ensuring consistent pressure and minimizing creases or uneven transfers in your vinyl.

Uniform heat distribution across the full working area reduces hot spots that can ruin designs. Non-stick properties prevent vinyl adhesion during removal, saving you time and frustration. In short, prioritize size, smoothness, durability, and non-stick performance to achieve reliable, professional results with every press.

Maintenance Considerations

Regular upkeep keeps your 15×20 clamshell press performing at its best. To maintain print quality, regularly clean the heat platen with a non-abrasive cloth and mild cleaning solution to prevent residue buildup that can affect transfers. Check and replace silicone pads or Teflon sheets periodically to sustain non-stick surfaces and shield the platen from damage.

Inspect electrical connections and control panels for wear or damage, ensuring safe and consistent operation. Calibrate temperature controls regularly to guarantee accurate heat settings and prevent uneven transfers or scorching. Store the heat press in a clean, dry environment to avoid rust, corrosion, and other environmental damage that could impair functionality.

These steps help you maximize reliability and results over time.

Frequently Asked Questions

What Is the Ideal Temperature Range for 15X20 Vinyl Transfers?

The ideal temperature range for 15×20 vinyl transfers is 305 to 320 degrees Fahrenheit. You’ll want to apply firm, even pressure for 12 to 15 seconds, then peel hot or cold depending on your vinyl type.

Adjust for materials.

How Long Should the Press Apply Heat for Typical Designs?

Typically, apply heat for 10–15 seconds for most designs, then check adhesion.

If needed, press again for 5 extra seconds. Use firm, even pressure, and keep the heat consistent to avoid scorching or ghosting.

Do Clamshell Presses Work Well on Uncoated or Coated Vinyl?

Clamshell presses work well on both uncoated and coated vinyl. They press evenly and protect your designs, like a loyal partner.

Just calibrate time and temperature, and you’ll avoid scorching or dulling the finish.

Is There a Safe Way to Preheat Garments Before Pressing?

Yes, you can safely preheat garments briefly before pressing. Use a low heat setting, short preheat time (2–5 seconds), and avoid excessive warmth to prevent scorching.

Remove wrinkles, then proceed with your heat transfer.

Can You Use a 15X20 Press for Sublimation or Only Vinyl?

Yes, you can use a 15×20 press for sublimation or vinyl. Think of it like a versatile kitchen stove: one burner handles many dishes.

With proper heat, time, and temperature, you’ll print vibrant sublimation as easily as vinyl.

Conclusion

If you’re weighing these 15×20 clamshells, trust the basics: solid build, accurate temperature, and dependable duty cycles matter far more than flashy presets. Don’t chase every new feature; instead, test even heating consistency across the plate and confirm auto-open works smoothly.

Consider your workspace and budget, then pick the model that shows steady performance under real use. A reliable press sticks with you through repeated projects, turning theory into dependable, hands-on results. When choosing the best vinyl heat press 15×20 clamshells for 2026, prioritize quality and consistency above all else.